2 月 . 16, 2025 07:19 Back to list

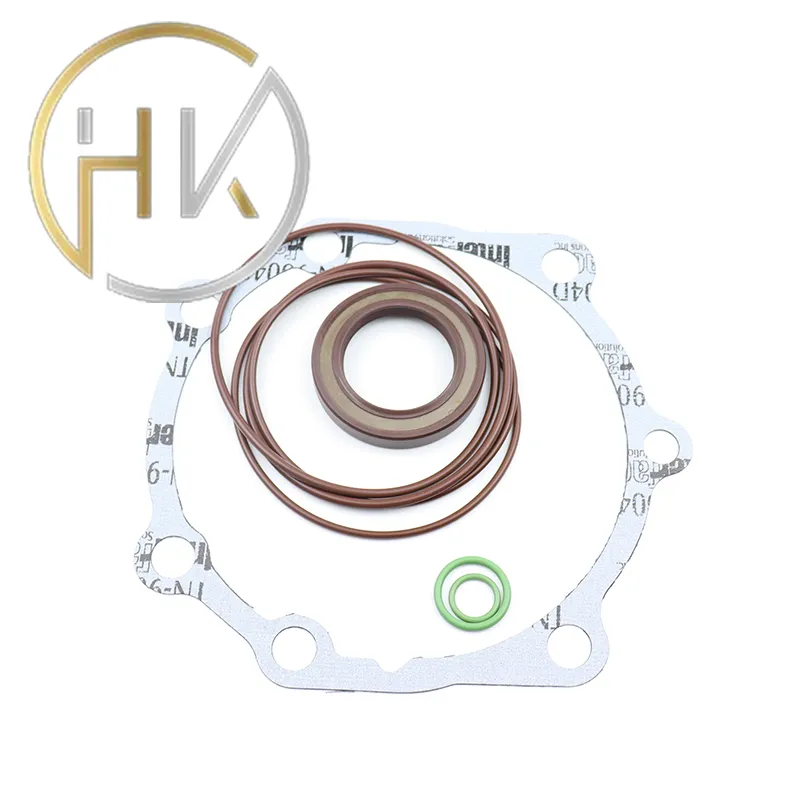

oil seal tcv

Trustworthiness is yet another critical aspect when dealing with combi oil seals. Machinery downtime due to seal failure can result in substantial operational losses and safety hazards. Reliable suppliers ensure their products undergo extensive quality inspections, including lifecycle testing and failure analysis, to guarantee outstanding performance and safety. Companies that consistently deliver on time and stand by their warranties build trust with their clientele, making them preferred partners in procurement decisions. The intersection of these four attributes—experience, expertise, authoritativeness, and trustworthiness—forms the foundation for successful implementation and sustainable performance of combi oil seals. Maintenance professionals and purchasing managers are encouraged to seek out partners who exemplify these qualities, ensuring that their machinery operates smoothly and efficiently with minimal disruption. Moreover, advancements in seal technology continue to emerge, driven by ongoing research and development efforts. As industries evolve, so too must the technology and standards surrounding critical components like combi oil seals. Engaging with industry leaders who are at the forefront of these developments can provide firms with a competitive edge, as they benefit from cutting-edge solutions that enhance operational efficiency and equipment longevity. In conclusion, the role of combi oil seals in industrial applications cannot be overstated. Their effectiveness is a testament to the blend of human experience, scientific expertise, authoritative production standards, and unyielding commitment to trust and reliability. Ensuring these elements are present in every step of the lifecycle—from design and manufacture to installation and maintenance—will support continued success and innovation in industries reliant on these critical components.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories