1 月 . 26, 2025 01:32 Back to list

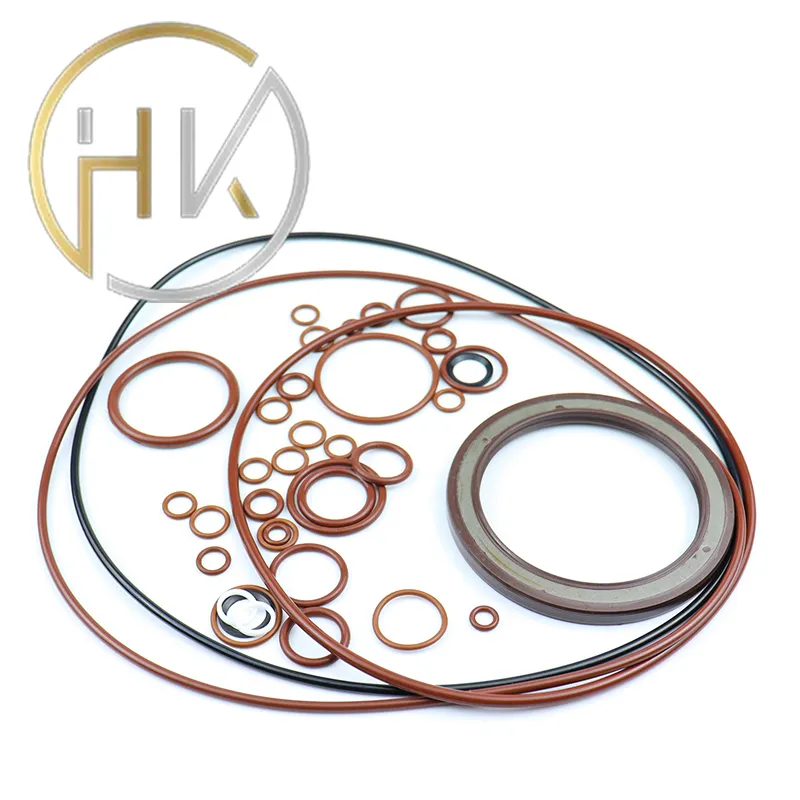

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Trustworthiness in the context of aftermarket hydraulic cylinder seal kits isn't just about product quality; it's about customer support and warranty. Reputable manufacturers understand that their responsibility extends beyond the sale. They provide robust customer support, ensuring that clients have access to technical assistance when necessary. Warranty policies should also be generous, providing coverage that instills confidence in the product's durability and the company's faith in their engineering. In practical applications, those who have switched to aftermarket solutions often report significant improvements in cost savings and machine uptime. For instance, industries that operate in harsh conditions, such as mining and forestry, have noted that the enhanced materials and design of aftermarket seal kits deliver reliable performance where OEM parts may have previously faltered. This firsthand experience underscores the viability of these kits, not just as a second choice but as a preferred solution when balancing performance and cost-effectiveness. The adoption of aftermarket hydraulic cylinder seal kits is a strategic decision informed by experience, expertise, authoritativeness, and trustworthiness. When chosen carefully, they provide a seamless fit and performance indistinguishable from, or sometimes superior to, original parts. Their role in preventive maintenance strategies cannot be overstated as they help in preempting leaks and failures, thus safeguarding expensive machinery and ensuring continuous operation. This proactive approach helps avoid costly repairs and potential operational downtimes, making them indispensable for businesses reliant on heavy machinery. Opting for aftermarket solutions doesn't just reflect a choice; it signifies a commitment to pragmatic, informed decision-making in the maintenance of hydraulic systems. As industries continue to seek ways to optimize operations, the role of high-quality aftermarket seal kits will continue to grow. By investing in these components, you're ensuring not just the health of your hydraulic systems, but also the overall efficiency and productivity of your operations.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories