1 月 . 19, 2025 00:32 Back to list

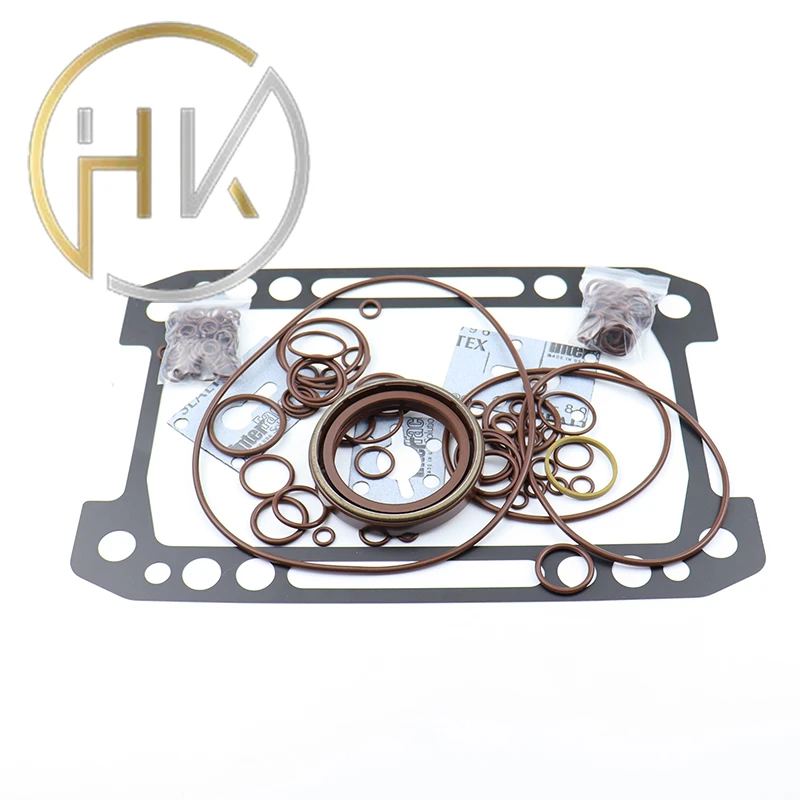

70x90x10 oil seal

Authoritative validation of this oil seal’s efficiency can be drawn from numerous industry-based case studies. Companies specializing in heavy machinery have documented improved operational efficacy post the integration of 70x90x10 oil seals, highlighting reduced downtimes and enhanced productivity. Testimonials from these giants in the machinery sector create a trustworthy narrative about the reliability of these seals, framing them as integral components for operational safety and efficiency. The trustworthiness of the 70x90x10 oil seal is further validated by its compliance with international standards. Many manufacturers ensure that their products meet or exceed these standards, certifying the seal's quality and performance. This compliance is crucial for maintaining industry trust, ensuring every oil seal product leaving the factory is ready to meet customer demands and expectations without compromise. Therefore, selecting the right oil seal is imperative for any mechanical setup aiming for seamless operation and longevity. Whether it’s for an automotive transmission system or an industrial pump, the 70x90x10 oil seal provides a reliable barrier against leakage and contamination. Its adoption across diverse sectors is a testament to its efficacy and trustworthiness. For companies and professionals seeking a durable and efficient sealing solution, this oil seal emerges as a preferred choice. Investing in high-quality components like the 70x90x10 oil seal substantiates a proactive strategy in machinery maintenance, promoting sustainability and operational excellence. It's not merely about sealing potential leaks; it's about preserving integrity and efficiency across mechanical systems. Hence, for those aiming for precision and reliability in their machinery components, the 70x90x10 oil seal remains a component worthy of consideration and adoption.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories