2 月 . 04, 2025 00:33 Back to list

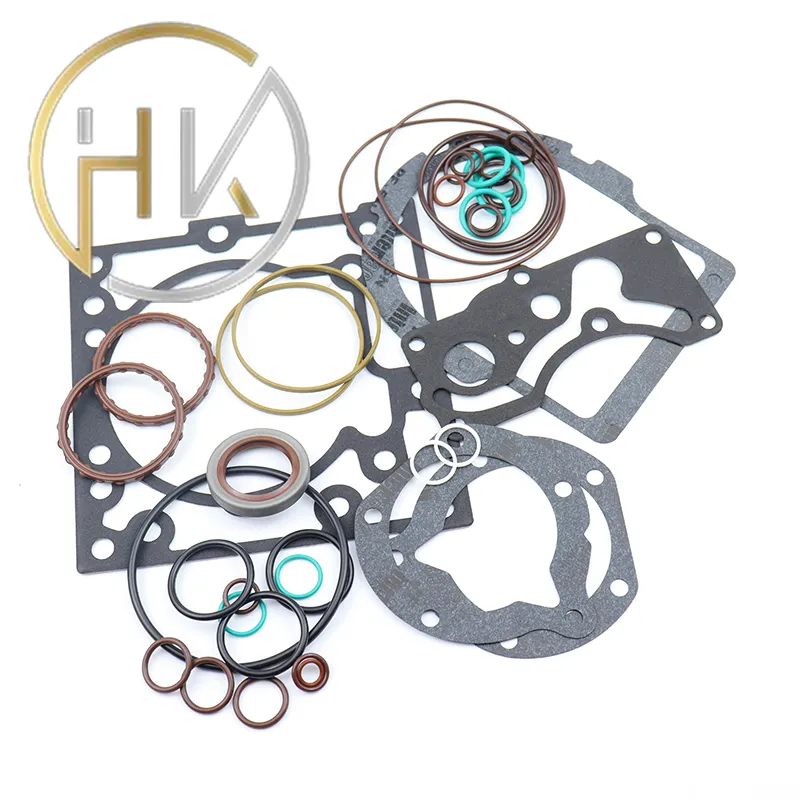

50x65x8 oil seal

Expert professionals in the sealing industry can attest to the importance of proper installation techniques to maximize the seal's effectiveness. Ensuring that the housing and shaft are clean and free of any burrs or sharp edges that could damage the seal during installation is vital. Adequate lubrication should be applied to the sealing lip and shaft to reduce friction during initial start-up, thereby preventing premature wear. For industries relying heavily on heavy machinery and mechanical systems, the role of oil seals cannot be overstressed. Their ability to act as barriers against contaminants, reduce operational noise, and improve the efficiency of mechanical systems by maintaining optimal lubrication levels makes them indispensable. Additionally, choosing high-quality oil seals such as the 50x65x8 not only provides peace of mind but also a tangible return on investment by prolonging equipment service life and enhancing reliability. Trust in application comes from a combination of rigorous quality controls and positive historical performance across various applications. Manufacturers of the 50x65x8 oil seal often adhere to international standards in their production processes, ensuring each seal meets stringent quality benchmarks before it reaches the market. This adherence to quality not only boosts the product's credibility but also instills confidence among engineers and maintenance professionals who utilize these seals in critical applications. Finally, as industries continue to evolve, the demand for reliable, high-performance components like the 50x65x8 oil seal is anticipated to grow. Businesses aiming to enhance their operational efficiency should consider investing in these tried-and-tested solutions crafted through decades of engineering expertise and innovation. By choosing a 50x65x8 oil seal, companies can ensure that their machinery remains in peak working condition, leading to enhanced productivity and reduced maintenance costs, ultimately propelling their competitive edge in today’s dynamic markets.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories