1 月 . 17, 2025 03:28 Back to list

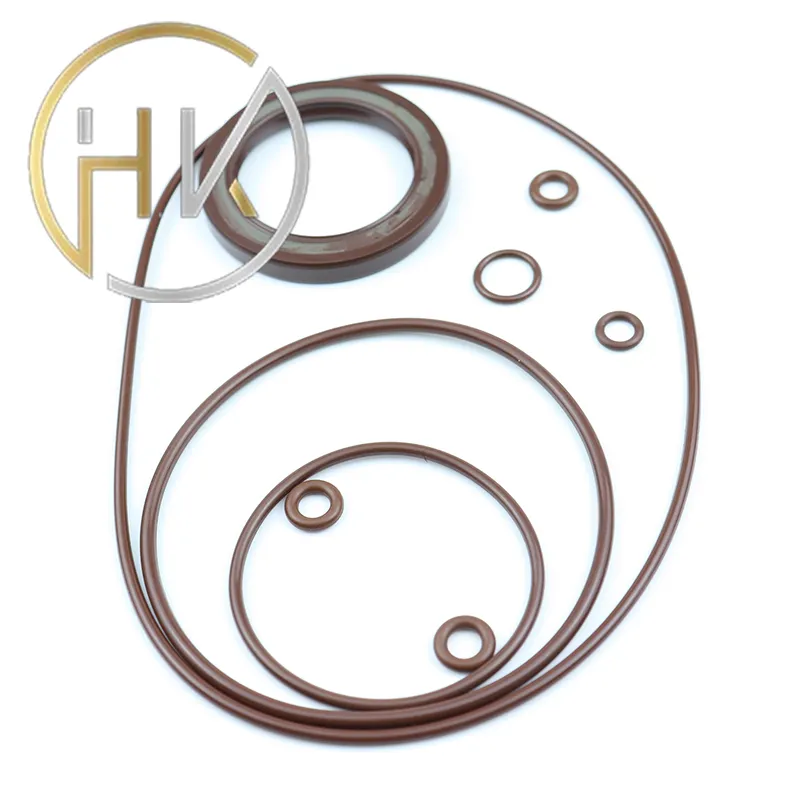

oil seal tcv

In terms of authority in the field, manufacturers of oil seals invest heavily in research and development to constantly enhance product capabilities. Industry leaders focus on advancing the design of oil seals to accommodate the increasing demands of modern machinery. Innovations include enhancing seal lip materials to better withstand various environmental exposures and incorporating design improvements that allow for greater tolerance of shaft misalignments. Trust in a brand or product, such as the 35x50x8 oil seal, stems from proof of performance and reliability over time. When purchasing a seal, it’s crucial to consider not just the product specifications, but also the reputation of the manufacturer. Companies with a strong track record of delivering high-performance seals can offer greater assurance, backed by rigorous testing and quality certification processes. For those considering an upgrade or replacement, the 35x50x8 oil seal stands out as an investment in operational efficiency and equipment longevity. When selecting this oil seal, ensure that it matches the specifications of your machinery and is suitable for the intended application environment. Consulting with engineers or experts can provide further insights and suggestions tailored to specific needs and operational conditions. In conclusion, the 35x50x8 oil seal is more than just a component; it is an essential part of machinery that contributes to performance continuity and cost savings through reduced maintenance. This specific size is a testament to precision engineering, offering compatibility and efficiency in various industrial applications. Whether for maintenance or new installations, investing in high-quality oil seals from reputable brands ensures machinery operates at its best, maintaining productivity and reducing downtime.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories