1 月 . 15, 2025 09:56 Back to list

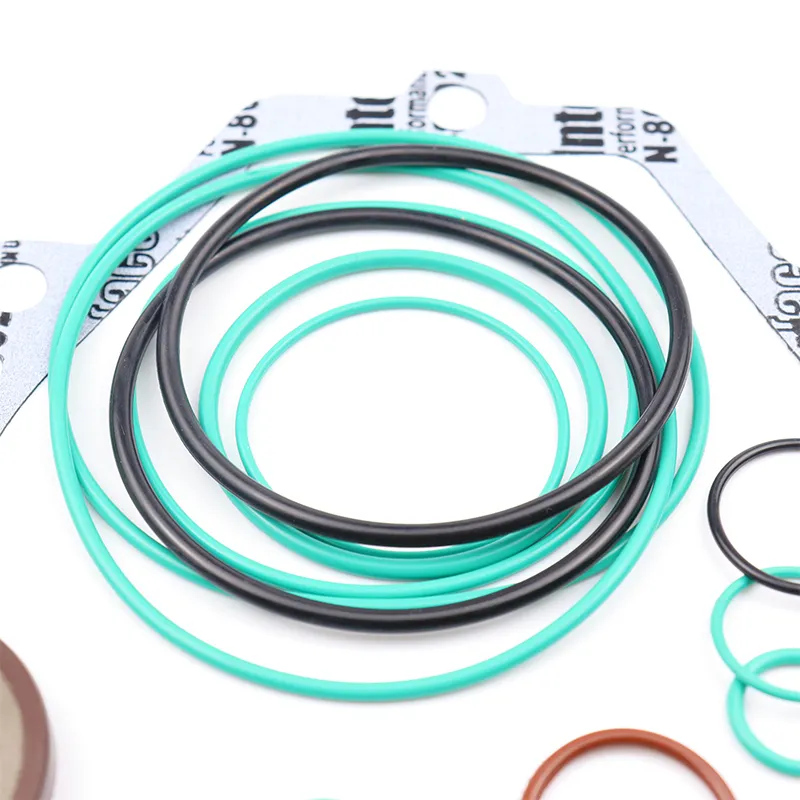

dkb seal

Trust is paramount in any application involving seals, as failure could lead to catastrophic system breakdowns. Testimonials from industry leaders and case studies serve as a testament to the robustness of the 32x47x7 seal. For instance, in the automotive industry, where every component must align perfectly for optimal performance, the use of these seals has been reported to reduce maintenance needs and extend the service interval of components. Similarly, in the industrial machinery sector, these seals have been credited with enhancing the longevity of equipment by minimizing the ingress of dirt and moisture. It is this blend of empirical evidence, backed by authoritative testing and supported by real-world application success, that culminates in the trustworthy nature of the 32x47x7 seal. As industries continue to expand and demand more efficient and reliable components, the place of these seals is firmly established. Whether you're an engineer, a buyer, or someone involved in maintenance, understanding the critical role of seals and choosing the right specification—such as the 32x47x7—can profoundly impact the operational success of your machinery.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories