2 月 . 05, 2025 00:33 Back to list

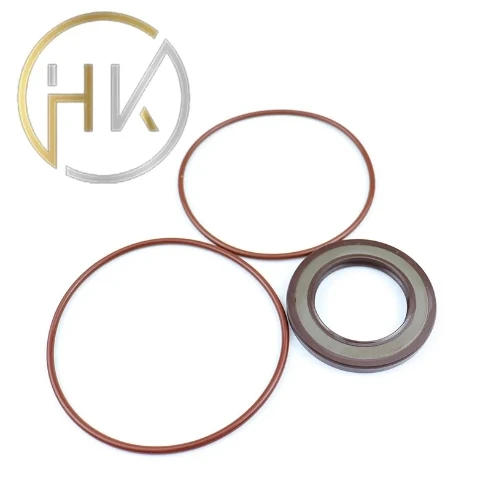

30x52x7 seal

Advanced manufacturing techniques, including precision molding and quality control testing, ensure that each seal meets stringent industry standards. For professionals in the field, understanding these design principles is foundational in selecting the right seal for a given application. Authoritativeness Industry Standards and Certification In terms of authority, seals like the 30x52x7 are often developed in compliance with international standards such as ISO and ASTM, which dictate the specifications and quality requirements for mechanical seals. Companies manufacturing these seals often undergo rigorous audits to achieve certification, attesting to their product's reliability and performance in critical applications. Manufacturers with robust R&D facilities and a strong track record in seal production are typically seen as leaders in innovation, often pushing the limits of seal technology to provide enhanced durability and efficiency. These credentials give industry buyers confidence in the quality and performance of their 30x52x7 seals. Trustworthiness Building Trust Through Proven Performance Trust in the 30x52x7 seal is built through a history of proven performance across various industries. Customer testimonials and case studies often highlight scenarios where this seal prevented significant breakdowns and maintained machinery performance under adverse conditions. Furthermore, warranties offered by reputable manufacturers add a layer of security, reassuring users of the seal’s longevity and reliability. In summary, the 30x52x7 seal, while small in size, holds significant importance in the smooth operation of numerous industrial machines. Its success lies in a combination of precise engineering, adherence to global standards, and a steadfast reputation for performance. As industries continue to evolve, seals such as the 30x52x7 will remain indispensable in meeting the demands of modern machinery, ultimately contributing to greater efficiency and safety across applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories