1 月 . 16, 2025 04:22 Back to list

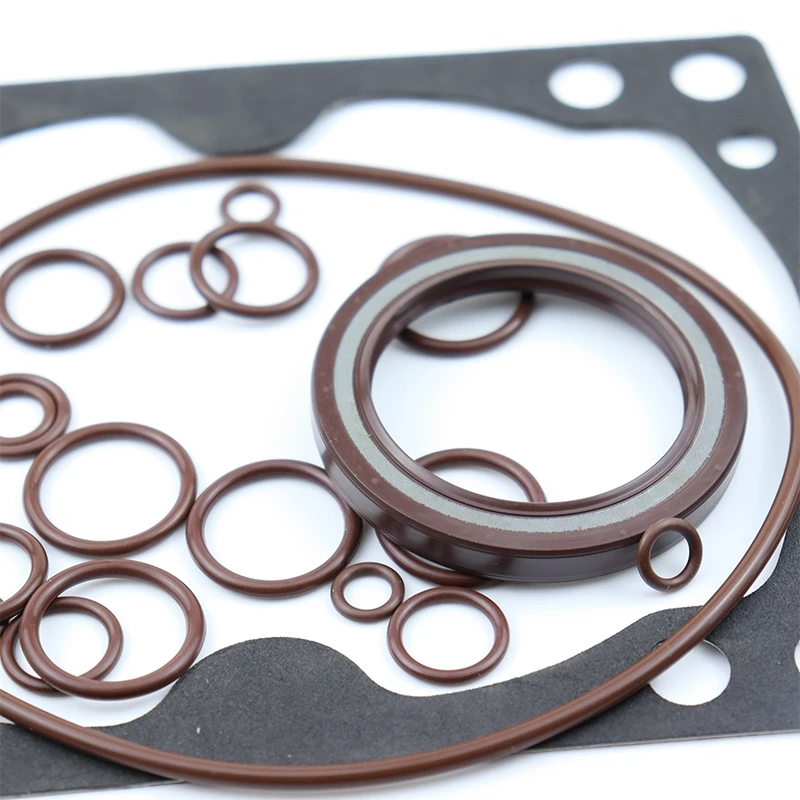

Standard High Pressure TCV Type Hydraulic Oil Seal

Authoritativeness in the context of oil seals can be demonstrated by understanding industry standards and specifications that govern their manufacturing and use. Products conforming to international standards, such as those set by the International Organization for Standardization (ISO), provide assurance of quality and compatibility. These standards guide manufacturers in producing reliable and efficient oil seals that meet various industrial demands. Trustworthiness is built by using oil seals from reputable manufacturers who comply with international standards and deliver consistent performance. Endorsed brands that have established a reputation for durability and responsiveness in harsh conditions are often preferred by professionals across sectors. Customer testimonials and case studies can further reinforce the trustworthiness of an oil seal, providing real-world examples of their effectiveness in practical applications. To capitalize on SEO, it’s crucial to incorporate phrases that prospective users might search for, such as high-performance 22 40 7 oil seal, or durable oil seals for industrial application. Content should revolve around the end user’s needs, addressing common questions and providing insightful solutions, thereby positioning the webpage as a resource-rich destination. With experience, expertise, authoritativeness, and trustworthiness as the foundational pillars of the content, the website will be well-placed to rank favorably in search engine results, ensuring visibility to a broader audience seeking information on oil seals.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories