10 月 . 02, 2024 11:42 Back to list

wiper seals

Understanding Wiper Seals Their Importance and Functionality

Wiper seals are crucial components in various applications, especially in hydraulic and pneumatic systems, as well as in automotive and industrial machinery. These seals play a vital role in preventing the leakage of fluids, protecting system components from contamination, and ensuring the efficient operation of machinery. Understanding wiper seals is essential for anyone involved in maintenance, repair, or the design of equipment that relies on these integral parts.

What is a Wiper Seal?

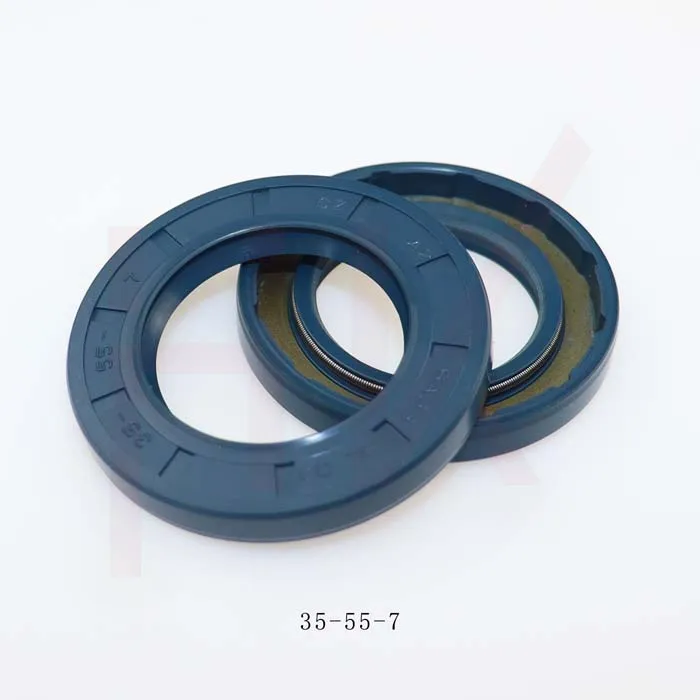

A wiper seal, also known as a dust seal or scraper seal, is specifically designed to prevent dirt, dust, and other contaminants from entering the system while also displacing any fluid or debris on the surface of the shaft. Typically made from rubber, polyurethane, or other flexible materials, wiper seals are engineered to withstand harsh environments and provide reliable performance. They are most commonly used in hydraulic cylinders, pneumatic cylinders, and automotive applications such as steering systems and shock absorbers.

How Wiper Seals Work

When a shaft moves in and out of a cylinder, the wiper seal is positioned at the outer edge of the cylinder. As the shaft extends or retracts, the wiper seal slides against the shaft, effectively scraping away any dirt or debris that may have accumulated. This action is vital because contaminants can cause significant damage to the internal components of a system, leading to wear, corrosion, and eventual failure. By keeping the working area clean, wiper seals extend the lifespan of machinery and improve overall performance.

Benefits of Wiper Seals

1. Contamination Prevention The primary function of wiper seals is to keep contaminants out of hydraulic and pneumatic systems. This is especially important in high-pressure applications where even a small amount of dirt can lead to catastrophic failure.

wiper seals

2. Fluid Retention Although wiper seals are not primarily designed to retain fluid, they do help minimize leakage from the systems they protect. This reduces maintenance costs and improves efficiency by ensuring that machinery operates with the necessary amount of fluid.

3. Enhanced Performance By preventing wear and tear caused by contamination, wiper seals help maintain the efficiency and effectiveness of mechanical systems. This can lead to smoother operation, better response times, and reduced energy consumption.

4. Versatility Wiper seals are available in various designs and materials to suit different environments and applications. Whether in extreme temperatures, high pressures, or corrosive conditions, the right wiper seal can provide reliable protection.

Maintenance and Replacement

To ensure optimal performance, wiper seals should be inspected regularly for signs of wear, damage, or deformation. Signs of failure may include fluid leaks or a noticeable decrease in operational efficiency. When replacing wiper seals, it is crucial to choose the correct size and material suitable for the specific application to avoid future complications.

Conclusion

Wiper seals are small yet significant components that play a critical role in the longevity and functionality of hydraulic and pneumatic systems, as well as various machinery. Understanding their role can lead to better maintenance practices, increased equipment reliability, and ultimately, a more efficient operation. In a world increasingly dependent on complex machinery, ensuring that every part works effectively—including wiper seals—can make all the difference in performance and durability.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories