10 月 . 02, 2024 17:05 Back to list

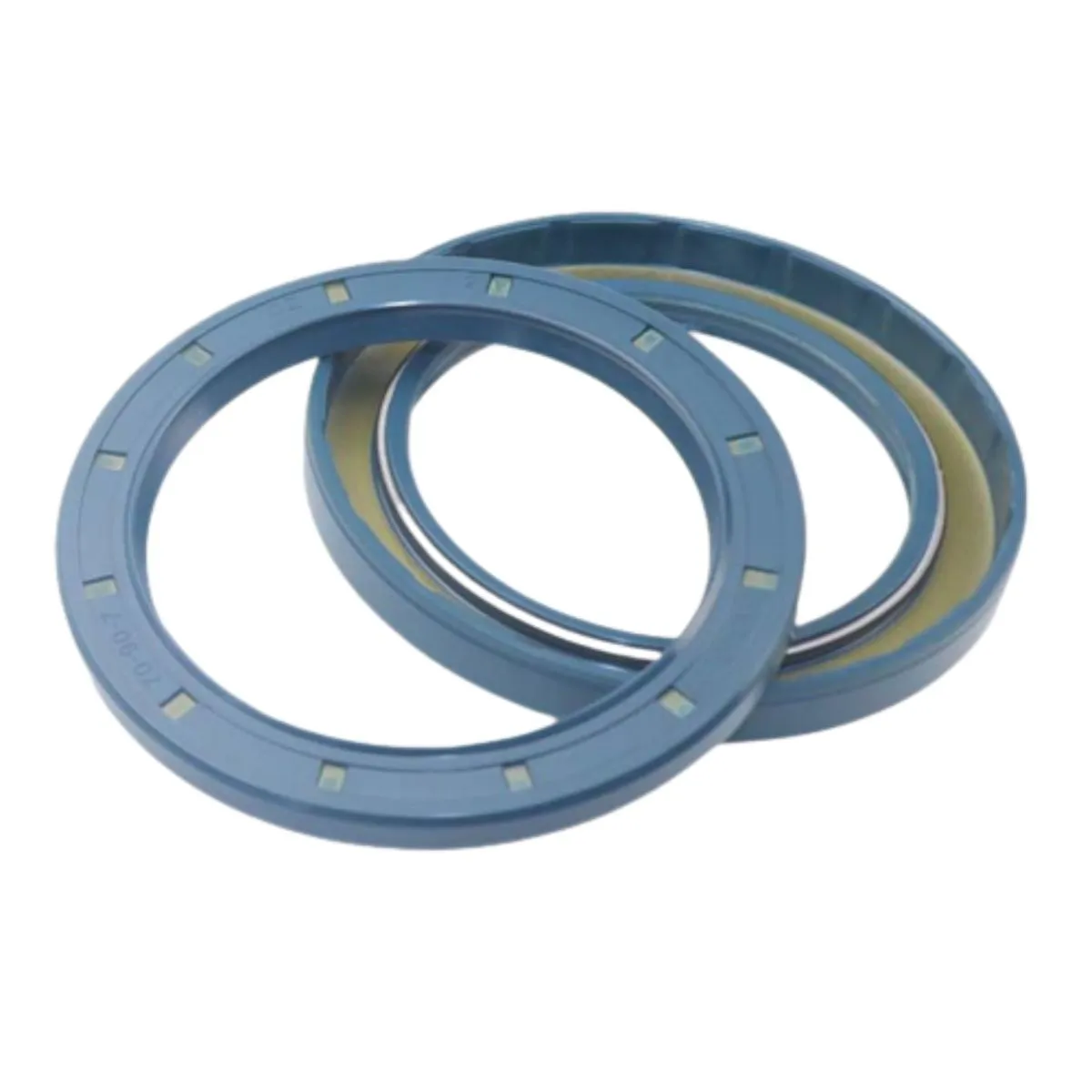

wiper ring piston

Understanding Wiper Rings in Hydraulic Pistons

Wiper rings play a critical role in the functionality and longevity of hydraulic pistons. These seemingly simple components are pivotal in ensuring the efficiency of hydraulic systems, which are widely used in various industries such as automotive, aerospace, and manufacturing. In this article, we explore the significance of wiper rings, their design features, and their importance in hydraulic piston applications.

Understanding Wiper Rings in Hydraulic Pistons

The design and materials used in wiper rings are crucial for their performance. Typically made from elastomers like polyurethane or rubber, wiper rings are engineered to withstand not only the mechanical stress from the reciprocating motion but also the harsh conditions of hydraulic fluids. These materials offer excellent wear resistance and can adapt to a wide range of temperatures, ensuring optimal performance in various demanding environments.

wiper ring piston

Wiper rings come in several designs, each tailored to specific applications. The most common design features a lip or a series of lips that create a tight seal against the piston rod. This design not only ensures that contaminants are effectively wiped away but also minimizes the possibility of hydraulic fluid leaking out. Additionally, some wiper rings incorporate special shapes or grooves to improve their wiping action and reduce the buildup of debris.

In hydraulic systems, the importance of maintaining a clean environment cannot be overstated. Contaminated hydraulic fluid can lead to hydraulic system failure, resulting in costly repairs and downtime. By utilizing high-quality wiper rings, companies can significantly reduce maintenance costs and improve the reliability of their systems. Regular inspection and timely replacement of worn wiper rings are essential best practices that contribute to the overall efficacy and safety of hydraulic equipment.

Furthermore, advancements in technology have led to the development of innovative wiper ring designs. Newer materials and manufacturing processes have enhanced the durability of these components, enabling them to function effectively in extreme conditions. As industries continue to evolve and demand more efficient hydraulic systems, the role of wiper rings will remain vital.

In conclusion, wiper rings are essential components in hydraulic piston systems that protect against contamination, enhancing the performance and longevity of hydraulic equipment. Their specific design features and material properties make them indispensable in ensuring the smooth operation of hydraulic machinery. For engineers and maintenance professionals alike, understanding the functional aspects and maintenance of wiper rings is key to optimizing hydraulic system performance and maximizing operational efficiency.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories