10 月 . 31, 2024 01:30 Back to list

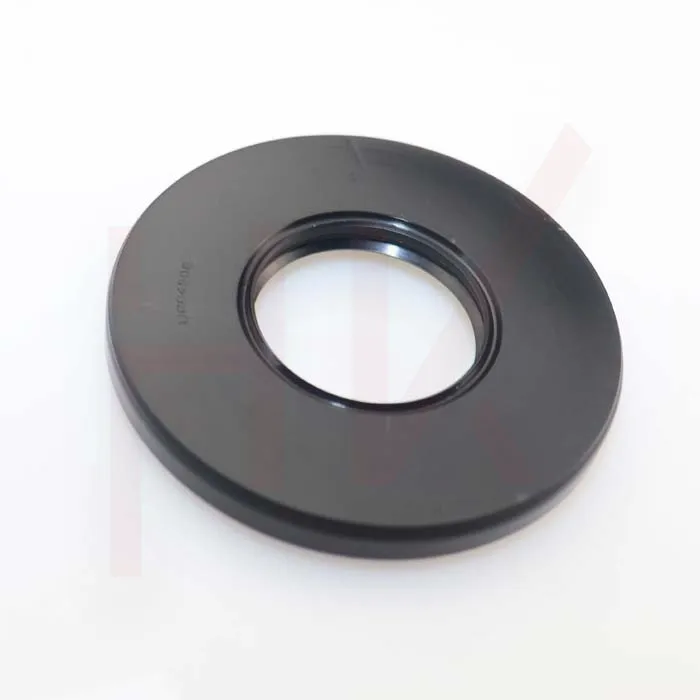

wheel bearing hub seal

The Importance of Wheel Bearing Hub Seals in Automotive Performance

Wheel bearing hub seals play a crucial role in the functionality and longevity of a vehicle's wheel assembly. These seals, which are often overlooked during routine maintenance, are essential for ensuring the smooth operation of wheel bearings while protecting them from contamination and lubricant loss. Understanding their function, types, and the importance of regular maintenance can help vehicle owners appreciate these components and avoid costly repairs.

What is a Wheel Bearing Hub Seal?

A wheel bearing hub seal is a component designed to keep the lubricant contained within the wheel hub assembly. It forms a barrier that prevents dirt, water, and other contaminants from entering the bearing area. By maintaining a clean environment for the bearings, these seals help ensure optimal performance and reduce the risk of premature wear or failure.

Types of Wheel Bearing Hub Seals

There are various types of wheel bearing hub seals, predominantly classified into two categories conventional seals and oil seals. Conventional seals, often made from rubber, are designed to provide a good closure mechanism that can withstand varying temperatures and pressure levels. Oil seals, on the other hand, are specifically crafted to withstand the high friction and heat generated by wheel bearings under load. The choice between these seals will depend on the vehicle's design, usage conditions, and the manufacturer's recommendations.

The Importance of Wheel Bearing Hub Seals

wheel bearing hub seal

1. Protection Against Contamination The primary function of wheel bearing hub seals is to keep harmful elements out. Dirt, dust, and moisture can infiltrate the wheel hub assembly through poorly sealed areas. Once contaminants enter the bearing, they can cause significant damage, leading to eventual failure of the entire assembly.

2. Lubrication Retention Proper lubrication is vital for the effective functioning of wheel bearings. Wheel bearing hub seals minimize the loss of grease or oil from the hub, maintaining the necessary lubrication that reduces friction and enhances performance. Without these seals, the lubrication could quickly dissipate, leading to overheating and damage.

3. Cost-Effective Maintenance By using high-quality wheel bearing hub seals and ensuring they are properly installed, vehicle owners can save a significant amount on repairs in the long run. Regular inspection of these seals during routine vehicle maintenance can help detect any wear early on, preventing more extensive damage to the bearings and the need for more costly replacements.

4. Safety and Performance Well-functioning wheel bearing hub seals contribute directly to the safety and performance of a vehicle. Failures in this component can lead to wheel misalignment, ineffective steering, and even wheel lock-up in severe cases, all of which jeopardize not only the vehicle but also the safety of its occupants.

Conclusion

Wheel bearing hub seals may be small components, but they play a monumental role in automotive performance and longevity. By ensuring these seals are in good condition and replacing them when necessary, vehicle owners can enhance their vehicles' reliability and safety. Regular checks and maintenance not only prolong the life of the bearings but also contribute to a smoother and quieter driving experience. Investing in quality seals is a wise decision for any vehicle owner seeking to maintain optimal functionality and avoid unnecessary repair costs.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories