10 月 . 14, 2024 17:55 Back to list

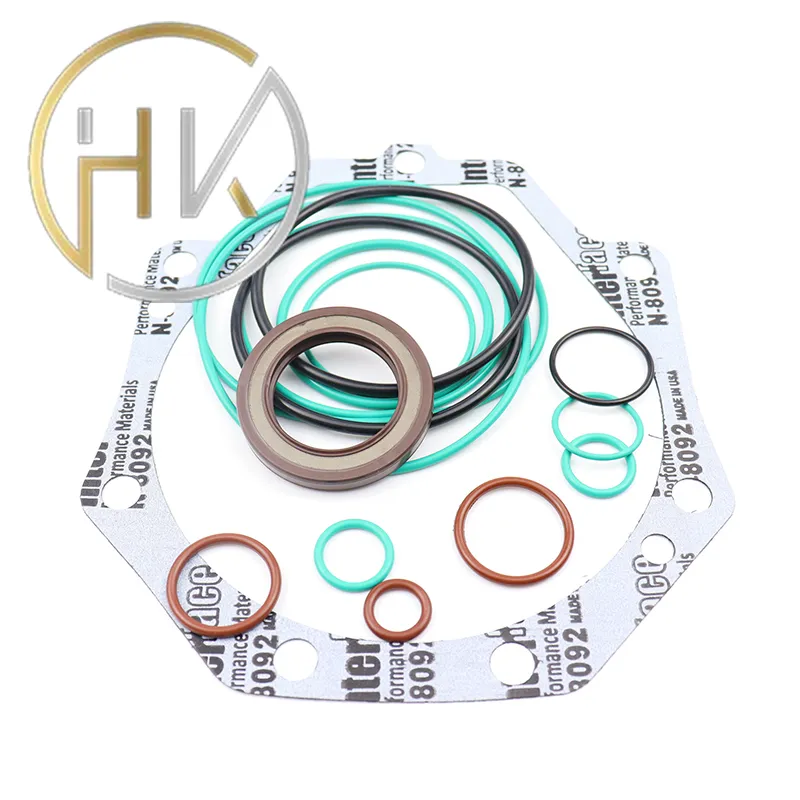

wheel bearing hub seal

Understanding Wheel Bearing Hub Seals Importance, Types, and Maintenance

Wheel bearing hub seals play a crucial role in the performance and longevity of a vehicle's wheel assembly. These seals are designed to protect the vital components of the wheel bearing from contaminants such as dirt, water, and other debris that can lead to premature wear and failure. They ensure that the lubrication within the bearing remains intact while preventing outside elements from infiltrating the assembly.

Importance of Wheel Bearing Hub Seals

The primary function of wheel bearing hub seals is to maintain the integrity of the wheel bearings. Wheel bearings are essential for allowing smooth rotation of the wheels, which is critical for vehicle performance. Without proper sealing, contaminants can compromise the lubrication of the bearings, leading to increased friction, heat, and ultimately, bearing failure. This can result in costly repairs and pose a safety risk on the road.

Moreover, a well-functioning seal contributes to the overall safety of the vehicle. The wheel hub assembly bears the weight of the vehicle and experiences significant stress while in motion. A compromised seal can lead to a loss of control while driving, which can endanger the lives of the passengers and others on the road.

Types of Wheel Bearing Hub Seals

There are various types of wheel bearing hub seals available in the market, each designed for specific applications. The two most common types are

1. Lip Seals These feature a flexible lip that makes contact with the surface of the bearing. They provide an effective barrier against contaminants while retaining lubrication. Lip seals are widely used due to their cost-effectiveness and reliable performance.

wheel bearing hub seal

2. Labyrinth Seals These consist of a series of grooves and channels that create a complex path for contaminants, making it difficult for them to reach the bearing. While labyrinth seals can be more expensive, they can offer superior protection, particularly in harsh environments.

Maintenance of Wheel Bearing Hub Seals

Proper maintenance of wheel bearing hub seals is essential to ensure their longevity and effectiveness. Here are some tips for maintaining wheel bearing hub seals

- Regular Inspection During routine maintenance, always check the condition of the seals. Look for signs of wear, cracking, or damage, which could indicate that they need to be replaced.

- Proper Installation When replacing seals, ensure that they are correctly installed. Misalignment can lead to premature failure.

- Quality Parts Use high-quality seals when replacing them, as inferior products may not provide adequate protection.

- Keep the Area Clean During maintenance, keep the area around the wheel assembly clean. Dirt and debris can easily enter the seal if it is compromised during installation or servicing.

In conclusion, wheel bearing hub seals are a vital component in maintaining the safety and performance of your vehicle. By understanding their importance and implementing proper maintenance practices, you can extend the life of your wheel bearings and ensure a smoother, safer driving experience. Regular checks and timely replacements will not only protect your vehicle but also contribute to a safer journey on the road.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories