8 月 . 21, 2024 20:35 Back to list

Understanding the Importance of Wiper Oil Seals in Automotive Maintenance

Understanding Wiper Oil Seals An Essential Component in Machinery

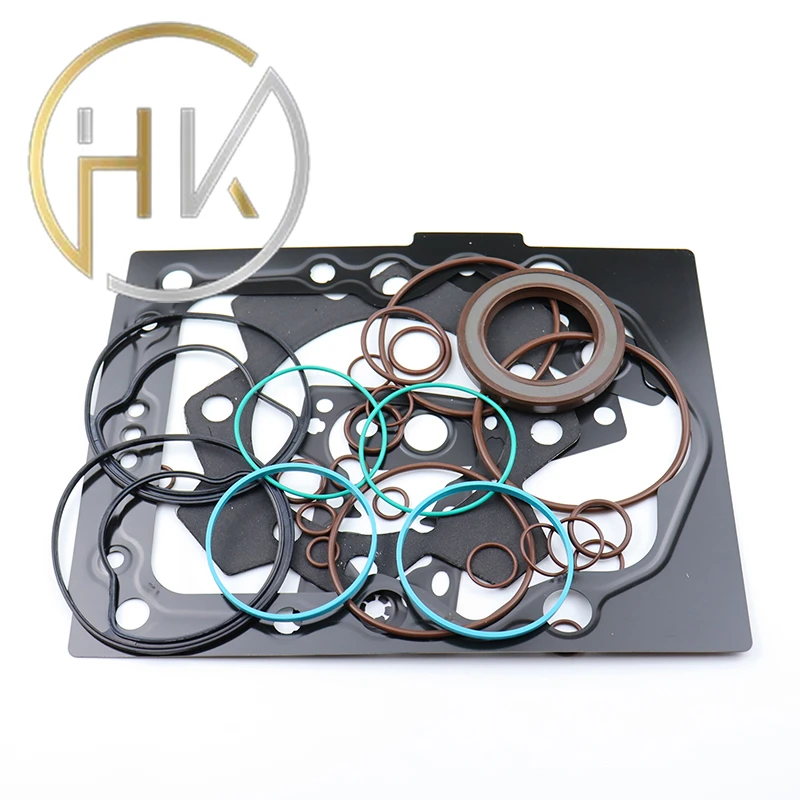

Wiper oil seals are critical components in various mechanical systems, particularly in vehicles and industrial machinery. These seals play a vital role in preventing the leakage of oil and contaminants, ensuring the smooth operation of moving parts. To understand the importance of wiper oil seals, it is essential to delve into their function, design, applications, and maintenance.

Function and Design

Wiper oil seals are designed to retain lubricant while preventing dirt, debris, and other contaminants from entering the system. They typically consist of a flexible elastomeric material that can withstand various environmental conditions, including temperature fluctuations and exposure to different chemicals. The primary function of an oil seal is to create a tight seal around a shaft, allowing for minimal leakage and optimal performance.

The design of wiper oil seals often incorporates a wiper lip, which is specifically engineered to remove contaminants from the shaft as it rotates. This wiper action is crucial in prolonging the life of bearings and other crucial components by keeping them clean and lubricated. The materials used in manufacturing these seals are selected based on the operating conditions they will face, which can include pressure, speed, and the type of lubricants used.

Applications

Wiper oil seals are commonly found in various applications, including automotive engines, hydraulic systems, pneumatic systems, and industrial machinery. In automobiles, these seals are often used in areas such as the crankshaft and camshaft, where they prevent oil from leaking out and contaminants from entering. In hydraulic systems, they play a significant role in ensuring that hydraulic fluid remains contained, allowing for effective and efficient operation.

wiper oil seal

Industrial applications also benefit from wiper oil seals, particularly in equipment that involves rotating shafts. The presence of wiper oil seals in these systems reduces wear and tear on bearings and other moving parts, which can save organizations substantial amounts in maintenance and replacement costs.

Maintenance and Care

Regular maintenance of wiper oil seals is crucial to ensure their longevity and effectiveness. Over time, these seals can become worn or damaged due to abrasion from contaminants or aging of the material. Signs of a failing oil seal can include visible leaks, noise from the bearings, or a decrease in performance.

To maintain wiper oil seals, it is essential to conduct routine inspections and replace them as necessary. Keeping the surrounding area clean and free of debris can also enhance the lifespan of these seals, as contamination is often a leading cause of seal failure. Additionally, using the correct type of lubricant that is compatible with the seal material can help prevent premature degradation.

Conclusion

In summary, wiper oil seals are indispensable components in a wide range of mechanical systems. Their primary function of retention of lubricants while preventing contamination cannot be overstated. Whether in automotive applications or industrial machinery, the role of these seals is crucial in maintaining the efficiency and longevity of equipment. With proper understanding and regular maintenance, wiper oil seals can provide reliable service, ensuring the optimal operation of various devices and machinery for years to come. As technology advances, so too will the design and materials used for wiper oil seals, further enhancing their functionality and application.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories