2 月 . 10, 2025 10:09 Back to list

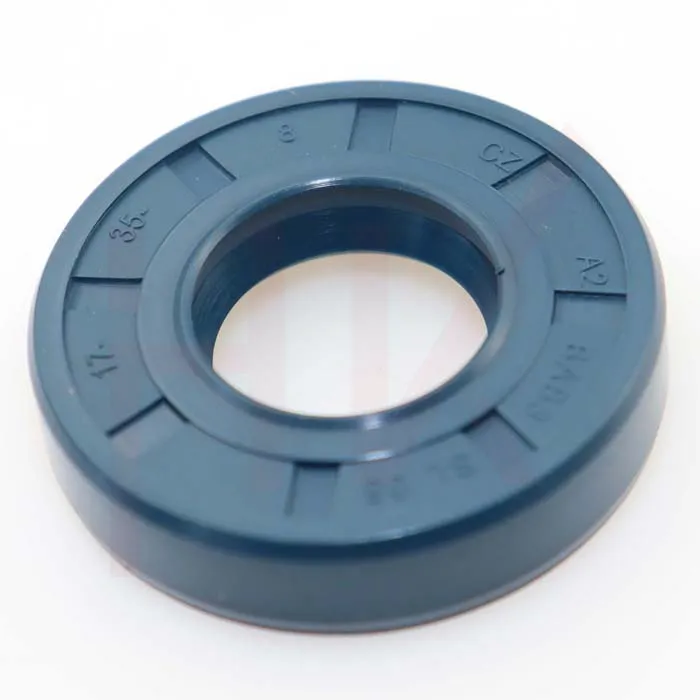

oil seal tcv

The authoritative use of TCN oil seals in the aerospace industry further underscores their importance. Aircraft engines, demanding the highest levels of precision and reliability, depend on these seals to prevent contamination and lubricant leakage. The aerospace sector's stringent regulatory requirements necessitate components that can withstand vibration, temperature fluctuations, and variable pressures. TCN oil seals, with their robust construction and trusted track record, meet these requirements with aplomb. Trust in TCN oil seals is fortified by their compliance with global manufacturing standards and certifications. These seals undergo rigorous testing and quality checks, ensuring they meet and exceed industry benchmarks for performance and durability. Manufacturers specializing in TCN oil seals invest in cutting-edge technology and materials research, continuously enhancing their products to meet evolving market needs. This commitment to quality and innovation builds confidence among industrial users, reinforcing the seal's reputation as a trusted guardian of machinery health. In conclusion, TCN oil seals are not just simple components; they are pivotal to the performance and reliability of complex machinery systems. Their expertly designed features, versatility across applications, and stringent adherence to quality standards ensure they remain unmatched in their field. Companies integrating TCN oil seals into their operations are investing in solutions born from a blend of expertise, trustworthiness, and authoritative engineering acumen. As industrial demands grow and evolve, TCN oil seals stand ready to meet the challenges, safeguarding machinery and enhancing efficiency across the board.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories