12 月 . 06, 2024 17:05 Back to list

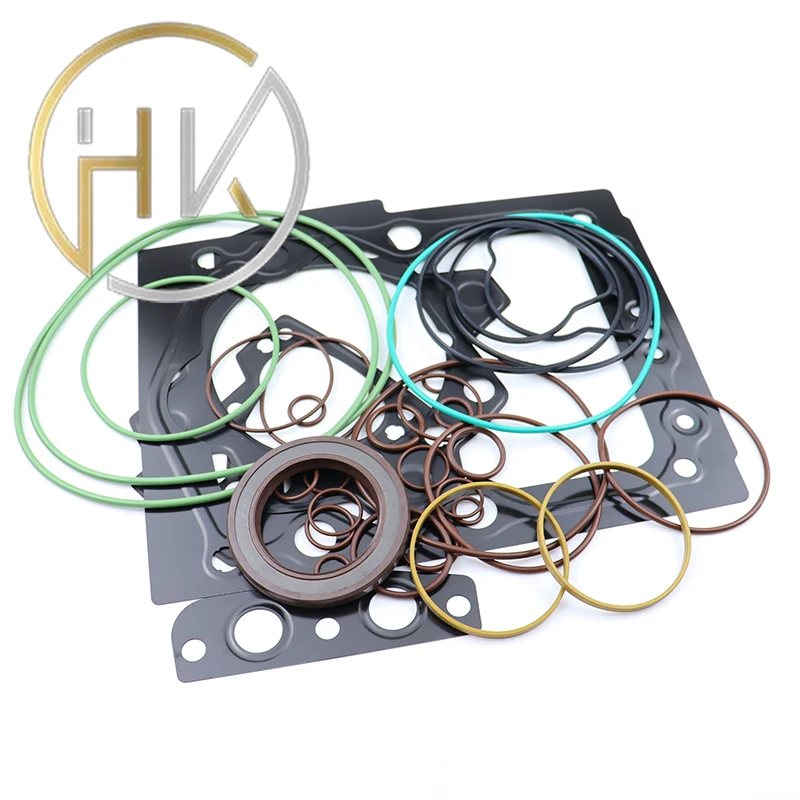

swivel hub seal

Understanding Swivel Hub Seals Importance and Functionality

Swivel hub seals are integral components used in various mechanical applications, primarily in vehicles and machinery that require the rotation of parts while simultaneously maintaining containment of lubricants and protection from environmental contaminants. These seals play a critical role in ensuring efficiency, longevity, and safety, making their understanding essential for engineers and mechanics alike.

What is a Swivel Hub Seal?

A swivel hub seal is designed to provide a sealing solution for rotating equipment. It typically consists of a flexible, rubber-like material that fits around a rotating shaft or hub. The seal's primary function is to keep lubricants in place while preventing dust, dirt, and moisture from entering the hub. This is particularly important in rotary applications, where a seal must accommodate both movement and potential misalignment.

The Importance of Seals in Machinery

In any mechanical system, lubrication is vital to reduce friction between moving parts. Without proper sealing, lubricants can leak out, leading to increased wear and tear, overheating, and ultimately, equipment failure. Swivel hub seals are thus essential in maintaining the integrity of bearings, gears, and other moving components. They protect machinery from contaminating agents and optimize performance by ensuring that lubrication remains effective for an extended period.

Key Features of Swivel Hub Seals

1. Material Composition Swivel hub seals are typically made from elastomers, such as nitrile or silicone rubber, which provide flexibility and resilience. The choice of material is critical, as it must withstand different temperatures, pressures, and chemical exposures.

2. Design and Configuration These seals come in various designs tailored to fit specific applications. Some may have additional features such as spring-loaded designs that enhance sealing performance under varying pressures and movements.

swivel hub seal

3. Installation and Maintenance Proper installation is crucial for the functionality of swivel hub seals. Incorrect installation can lead to premature failure, resulting in leaks and costly repairs. Regular inspection and maintenance are also necessary to ensure that seals remain in optimal condition and continue to perform effectively.

Applications of Swivel Hub Seals

Swivel hub seals are commonly utilized in various industries, including automotive, aerospace, and manufacturing. In vehicles, they are used in wheel hubs, suspension systems, and differentials to maintain lubrication and protect against grime and moisture. In industrial machinery, these seals are found in rotating shafts, conveyor systems, and hydraulic equipment, ensuring smooth operation and extending equipment lifespans.

Challenges and Innovations

Despite their importance, swivel hub seals can face challenges such as wear and degradation from exposure to environmental conditions and operational stresses. Advances in materials science have led to the development of enhanced seal materials that can withstand harsher environments, provide better friction resistance, and reduce the likelihood of failure.

Furthermore, innovative designs are being explored, including integrated sensors that monitor seal integrity and performance in real time. This can provide early warnings of potential failures, allowing for preventative maintenance and reducing downtime in critical applications.

Conclusion

In conclusion, swivel hub seals are vital components that contribute significantly to the performance and longevity of machinery and vehicles. Understanding their functions, features, and applications helps to appreciate their role in mechanical systems. As technology advances, the development of improved materials and designs will continue to enhance the effectiveness of swivel hub seals, ensuring safer and more efficient operations across various industries. For anyone involved in machinery maintenance or engineering, a comprehensive knowledge of swivel hub seals is essential for maintaining the integrity and efficiency of rotating systems.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories