2 月 . 13, 2025 17:43 Back to list

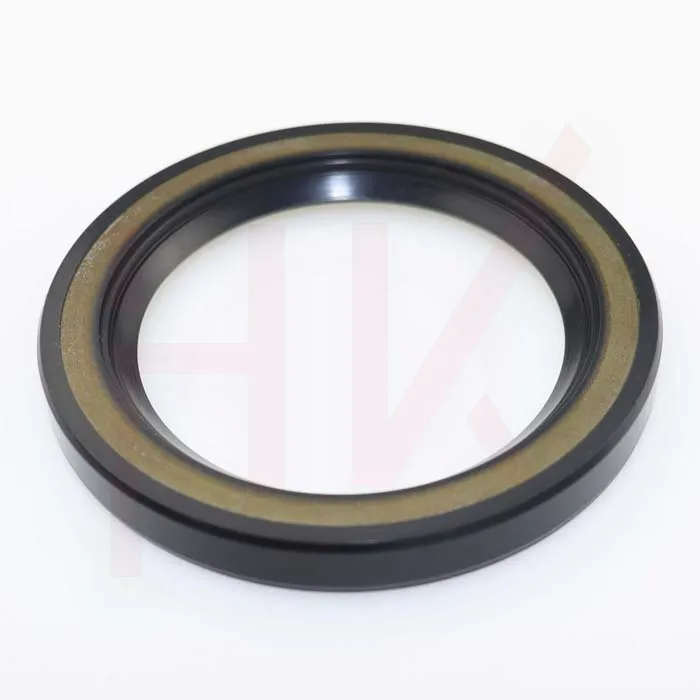

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Furthermore, trustworthiness in shaft wiper seal suppliers and manufacturers is non-negotiable. The industry relies heavily on the dependability of these providers to deliver products that meet rigorous quality standards and certifications. When sourcing shaft wiper seals, companies often look for manufacturers who adhere to ISO specifications, ensuring that the seals will perform reliably under specified conditions. Establishing a relationship with a reputable supplier guarantees access to replacement parts, technical insights, and product innovations. Real-world experience also highlights the diversity of applications beyond traditional industrial use. In the automotive sector, shaft wiper seals are employed in steering and suspension systems, where they play a pivotal role in protecting shock absorbers from dirt ingress. Here, the expertise in designing seals that can withstand extreme temperatures and pressures becomes evident. Similarly, in consumer appliances, these seals help maintain the functionality of motors by keeping them free from dust accumulation, showcasing versatility and adaptability across varied domains. The journey towards optimal machinery performance is incomplete without a comprehensive approach to sealing solutions, including shaft wiper seals. By combining material innovation with strategic application, these components underscore a blend of experience, expertise, authoritativeness, and trustworthiness. Their contribution not only ensures machinery longevity but also promotes sustainable operational practices, illustrating their indispensable role across industries. Thus, understanding the significance of shaft wiper seals from a holistic viewpoint encourages industries to invest in these components strategically. By prioritizing quality, employing specialist knowledge, and harnessing the expertise available, businesses can protect their investments and maximize efficiency, making shaft wiper seals not just components but key contributors to industrial success.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories