10 月 . 10, 2024 01:38 Back to list

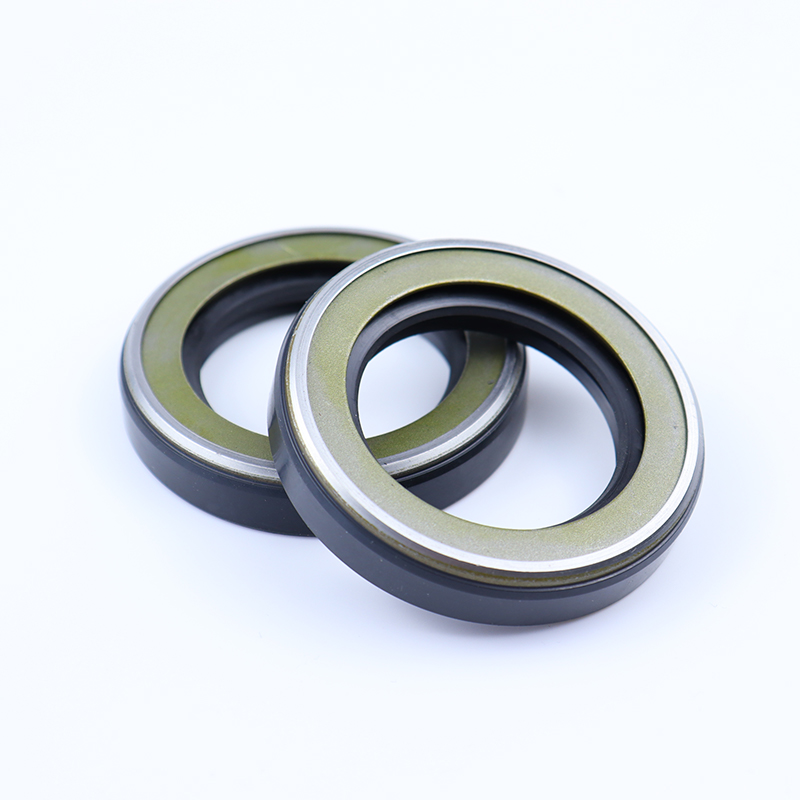

shaft wiper seal

Understanding Shaft Wiper Seals Essential Components for Equipment Longevity

Shaft wiper seals are critical components in numerous mechanical systems, serving the essential function of preventing contaminants from entering the machinery while also retaining lubrication. Though often overlooked, these seals are vital for the performance and longevity of equipment such as hydraulic cylinders, automotive engines, and various rotary and linear motion systems. In this article, we will delve into the purpose, design, and significance of shaft wiper seals, along with their applications across different industries.

The Purpose of Shaft Wiper Seals

The primary role of a shaft wiper seal is to protect the internal components of machinery from debris and contaminants such as dirt, dust, water, and oil. These particles, if allowed to infiltrate the system, can cause significant wear and tear, leading to reduced efficiency and even catastrophic failures. The wiper seal acts as the first line of defense, ensuring that only clean lubrication contacts the moving parts, thereby enhancing performance and extending operational life.

Design Features

Shaft wiper seals are designed with a specific geometry to optimize their sealing capabilities. Typically made from durable elastomers or thermoplastics, these seals are engineered to withstand harsh operating conditions, including extreme temperatures and pressures. The design often incorporates a lip that exerts pressure against the shaft, effectively scraping off any contaminants before they can penetrate the machinery.

Moreover, wiper seals can be customized based on the application requirements. For instance, different materials can be chosen based on the chemical compatibility with the fluids processed within the machinery. The size and shape of the seal can also be tailored to fit specific shafts, ensuring a precise fit that minimizes leakage and contamination.

Applications of Shaft Wiper Seals

shaft wiper seal

Shaft wiper seals find use in a variety of applications across different sectors. In hydraulic systems, these seals are crucial for preventing hydraulic fluid from leaking out while keeping contaminants away. In automotive applications, wiper seals are used in wheel bearings, steering systems, and engine components, protecting vital areas from dirt and moisture.

Industrial machinery, including pumps and conveyor systems, also relies on shaft wiper seals to maintain performance. The operation of these machines often involves exposure to rough environments, where dust and other particles can compromise their functionality. By integrating effective wiper seals, manufacturers can minimize maintenance costs and downtime, significantly enhancing productivity.

Importance in Maintenance

Regular inspection and maintenance of shaft wiper seals are essential to ensure optimal performance and prevent failures. Over time, seals can wear out due to friction, extreme temperatures, or chemical exposure. A damaged wiper seal can lead to leaks and contamination, which may require costly repairs or replacements of other components.

Implementing a proactive maintenance schedule that includes monitoring the condition of wiper seals can greatly reduce operational risks. Operators should always be vigilant for signs of wear, such as visual deterioration or changes in machinery performance, which can indicate that it’s time to replace the seals.

Conclusion

In summary, shaft wiper seals are indispensable elements in a wide range of mechanical systems. Their ability to keep contaminants at bay while maintaining effective lubrication is essential for the smooth operation of equipment. By understanding the design, applications, and maintenance of these seals, companies can ensure better performance and longevity of their machinery, ultimately leading to increased productivity and reduced operational costs. As industries continue to evolve and demand more reliable and efficient machinery, the importance of shaft wiper seals will only continue to grow, underscoring their role as an unsung hero in mechanical engineering.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories