10 月 . 06, 2024 21:07 Back to list

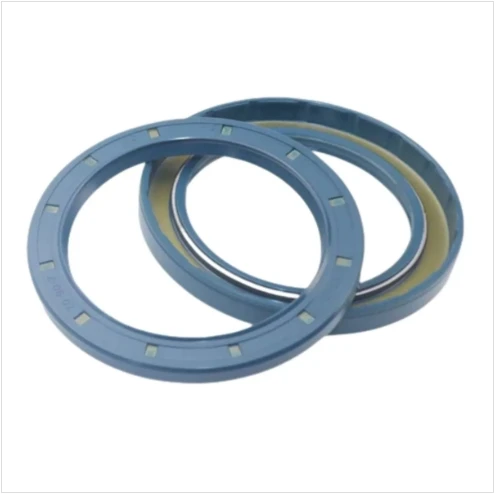

shaft wiper seal

Understanding Shaft Wiper Seals Importance and Applications

Shaft wiper seals play a crucial role in the functionality and longevity of various mechanical systems. They are engineered to prevent contaminants from entering machinery while simultaneously retaining lubrication within the assembly. These seals are vital components in many industries, including automotive, aerospace, and manufacturing, where they contribute to the performance and durability of rotating equipment.

What is a Shaft Wiper Seal?

A shaft wiper seal is a sealing device installed on the exterior of a rotating shaft. Its primary function is to wipe away contaminants, such as dirt, dust, and moisture, that could otherwise enter the internal mechanisms of machinery and cause wear or failure. This type of seal typically features a lip that makes contact with the rotating surface of the shaft, effectively wiping away external particles and preventing them from migrating into the system.

Construction and Materials

Shaft wiper seals are generally made from elastomers, plastics, or a combination of materials suited to the specific application. Common materials include rubber compounds such as nitrile, polyurethane, and silicone, which offer varying degrees of chemical resistance, temperature tolerance, and mechanical properties. The design of the seal can also vary, with options for different shapes and sizes to accommodate various shaft dimensions and operational environments.

Importance of Shaft Wiper Seals

1. Contamination Prevention The primary role of a wiper seal is to keep contaminants at bay. Without an effective seal, dirt and debris can enter the machinery, leading to premature wear and potential operational failures. For example, in hydraulic systems, even a small amount of contamination can compromise fluid quality, leading to system inefficiencies.

2. Lubrication Retention In addition to blocking contaminants, shaft wiper seals help retain lubricants within the assembly. Effective lubrication is critical for reducing friction between moving parts, which minimizes wear and tear and extends the service life of equipment. Maintaining a proper lubricant film also plays a significant role in preventing overheating and corrosion.

shaft wiper seal

3. Enhancing Operational Efficiency By ensuring that only clean substances contact moving parts, wiper seals contribute to the overall efficiency of machinery. Equipment that operates under optimal conditions tends to require less energy and experience fewer failures, leading to reduced maintenance costs and increased productivity.

4. Versatility Shaft wiper seals can be designed for a wide variety of applications. They are used in hydraulic cylinders, electric motors, gearboxes, automotive systems, and industrial machinery. Their versatility makes them an essential component in virtually every sector that involves rotating machinery.

Application Examples

Automotive Industry In cars, shaft wiper seals are found in various components such as power steering systems, transmission assemblies, and engine oil seals. They protect sensitive components from dirt and moisture, ensuring smooth operation and longevity.

Hydraulic Systems In hydraulic cylinders, wiper seals help to prevent contaminants from entering the cylinder bore. This is particularly important as hydraulic systems require clean oil to operate effectively. The seal aids in maintaining hydraulic pressure and functional efficiency.

Aerospace In the aerospace sector, wiper seals are used in landing gear mechanisms and hydraulic systems to ensure reliable operation even in harsh environmental conditions. These seals must withstand extreme temperatures and pressures while providing effective sealing.

Conclusion

Shaft wiper seals are indispensable components that ensure the reliability, efficiency, and longevity of various mechanical systems. Their ability to prevent contamination and retain lubrication makes them a key element in maintaining optimal performance. As industries continue to advance and demand higher efficiency and reliability, the role of wiper seals in machinery will only become more critical. Understanding their importance and applications can help engineers and maintenance professionals make informed decisions about equipment maintenance and management, ultimately leading to improved performance and reduced operational costs.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories