1 月 . 30, 2025 03:42 Back to list

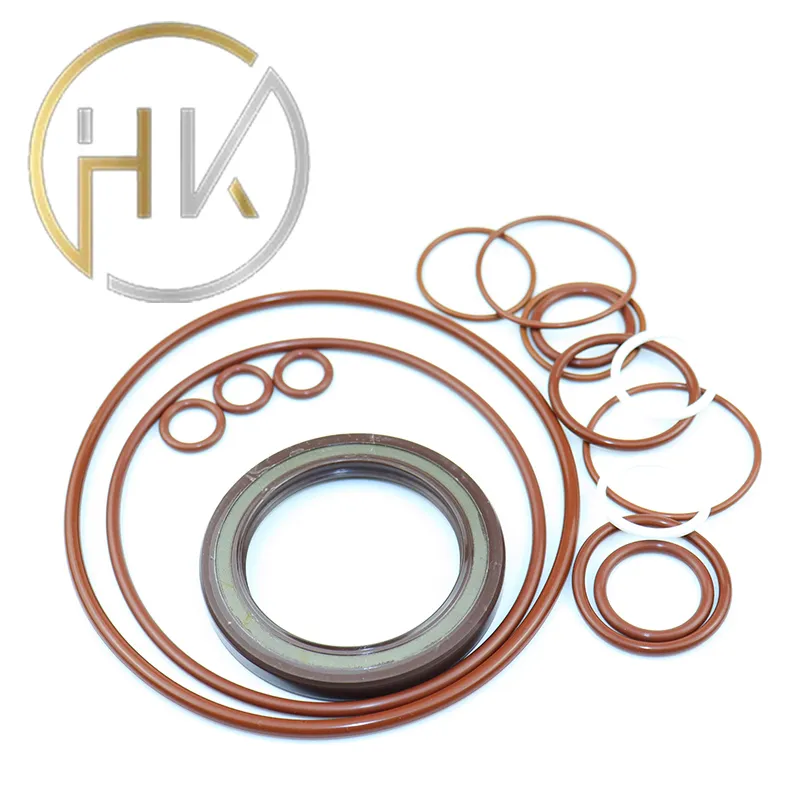

shaft oil seal

Authoritative knowledge on shaft wipers reveals a complex interdependence between the machinery and its protective elements. Trusted industry experts emphasize the need for compatibility between shaft wipers and the shafts themselves, noting that a mismatch can lead to reduced efficiency or even complete machine failure. Thus, industry leaders advocate for precision in sizing and installation, confirming that these components are not just add-ons but are intrinsic parts of the system. The credibility of shaft wipers is further corroborated by their extensive application across various mechanical domains. They serve a diversity of sectors including aerospace, oil and gas, and robotics, showcasing their robustness and adaptability. Trusted manufacturers and suppliers of shaft wipers often provide custom solutions tailored to specific industry needs, fortifying their reputation as reliable partners in machinery sustainability and operation. In terms of trustworthiness, the consistent dependability of shaft wipers fosters confidence among engineers and operators. Their role in safeguarding machinery against pollution by enabling effective sealing is a testament to their reliability. Trust is also built on empirical evidence; numerous case studies document how effective shaft wipers have prevented system failures and improved operational efficiencies across sectors. Choosing a shaft wiper involves considering several factors the type of application, environmental conditions, material compatibility, and installation requirements. Industry professionals recommend engaging with suppliers who have a proven track record of excellence in manufacturing and who offer comprehensive customer support. This ensures that any concerns or requirements specific to the application are adequately addressed, enhancing the reliability and performance of the shaft wipers deployed. Ultimately, shaft wipers are indispensable in any robust mechanical setup, providing critical protection and efficiency enhancements. The expertise necessary to select, install, and maintain these components can be the deciding factor in achieving optimal mechanical operations. As industries evolve with technological advancements, the role of shaft wipers continues to be integral, underscoring their relevance in the modern mechanical landscape. By partnering with trusted suppliers and utilizing expert knowledge, industries can ensure their machinery remains protected and operationally sound, highlighting the irreplaceable value that shaft wipers bring to modern engineering solutions.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories