10 月 . 16, 2024 08:45 Back to list

Hydraulic Seals for Kits Essential Components for Equipment Performance and Longevity

Understanding Seal Kit Hydraulics Essential Components for Optimal Performance

In the realm of machinery and industrial systems, hydraulic systems play a crucial role in providing the necessary power for a wide array of applications, from construction equipment to manufacturing machinery. At the heart of these hydraulic systems lies a vital component known as the seal kit. These kits ensure the effectiveness, reliability, and longevity of hydraulic operations. In this article, we will explore the significance of seal kits in hydraulic systems, their components, and best practices for maintenance.

The Role of Seal Kits in Hydraulic Systems

A hydraulic system operates on the principle of fluid under pressure. To maintain this pressure and prevent leaks, seal kits are essential. They consist of various seals, O-rings, and packing used to ensure that hydraulic fluid remains contained within the system, thus preventing loss of pressure and protecting against contamination. The primary function of these seals is to provide a barrier between components, ensuring that the hydraulic fluid circulates efficiently through the system.

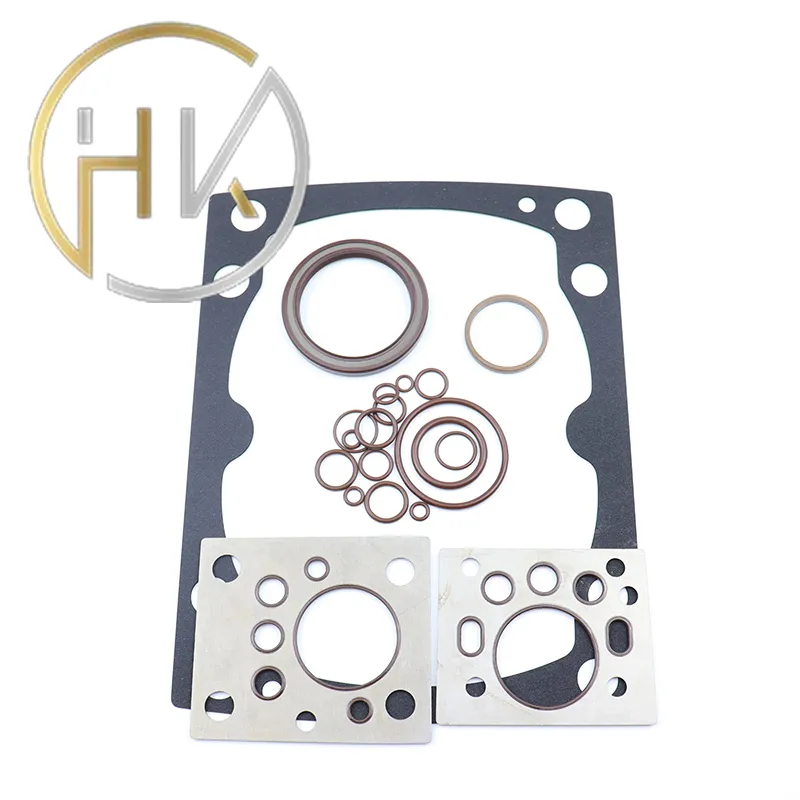

Components of a Seal Kit

A typical seal kit consists of several key components

1. O-Rings These circular loops of elastic material are one of the most common types of seals used in hydraulic systems. They are designed to fit snugly into grooves on hydraulic components, preventing the escape of fluid while accommodating movement.

2. Back-up Rings Often used in conjunction with O-rings, back-up rings are placed behind O-rings to provide additional support and prevent extrusion under high pressure.

3. Rod Seals These seals are specifically designed for hydraulic rods. They prevent leakage along the rod's surface as it moves in and out of the cylinder.

5. Wipers Wiper seals are essential for keeping dirt and debris out of hydraulic cylinders. They wipe the rod as it retracts, ensuring that contaminants do not enter the hydraulic system.

6. Gaskets Used to seal the mating surfaces of hydraulic components, gaskets prevent fluid leakage where parts are joined.

seal kit hydraulic

Importance of Quality Seal Kits

Using high-quality seal kits is paramount for the effective performance of hydraulic systems. Low-quality seals can wear out quickly, leading to leaks, reduced efficiency, and ultimately costly downtime. Investing in quality seal kits ensures that machinery operates smoothly, minimizing wear and extending the lifespan of components. Organizations should always opt for seals that meet industry standards and are suitable for their specific hydraulic fluids and operating conditions.

Maintenance Best Practices

To ensure the longevity and effectiveness of hydraulic seal kits, regular maintenance is crucial. Here are some best practices to follow

1. Regular Inspections Inspect hydraulic systems periodically for signs of leakage or wear. Early detection can prevent more significant issues down the line.

2. Keep Components Clean Contamination is one of the leading causes of hydraulic system failure. Regularly clean the components and ensure that the hydraulic fluid is free from particulates and moisture.

3. Monitor Fluid Levels Always maintain the correct fluid levels in the reservoir. Low fluid levels can lead to inadequate lubrication and increased wear on seals.

4. Replace Worn Seals Promptly If any seals show signs of wear or damage, replace them immediately to prevent system failure.

5. Consult Manufacturer Recommendations Follow the guidance provided by manufacturers regarding seal selection, installation, and maintenance schedules.

Conclusion

Seal kits are an indispensable part of hydraulic systems, ensuring the safe and efficient operation of various machinery and equipment. Understanding the components and functions of seal kits, along with adhering to maintenance best practices, can significantly enhance the reliability and efficiency of hydraulic operations. By investing in quality seal kits and performing regular inspections, businesses can minimize downtime and extend the lifespan of their hydraulic systems, ultimately leading to increased productivity and profitability.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories