9 月 . 29, 2024 02:32 Back to list

Seal Kit Solutions for Cylinder Maintenance and Repair Needs

Understanding Seal Kits for Cylinders Essential Components for Hydraulic and Pneumatic Systems

In various engineering applications, seal kits play a crucial role in maintaining the efficiency and longevity of hydraulic and pneumatic cylinders. A seal kit for a cylinder typically includes all the necessary rubber and polymer seals required for the repair or maintenance of hydraulic and pneumatic systems. These kits are essential for ensuring that cylinders operate smoothly, safely, and without leaks, which can lead to system failure or inefficiencies.

What is a Seal Kit?

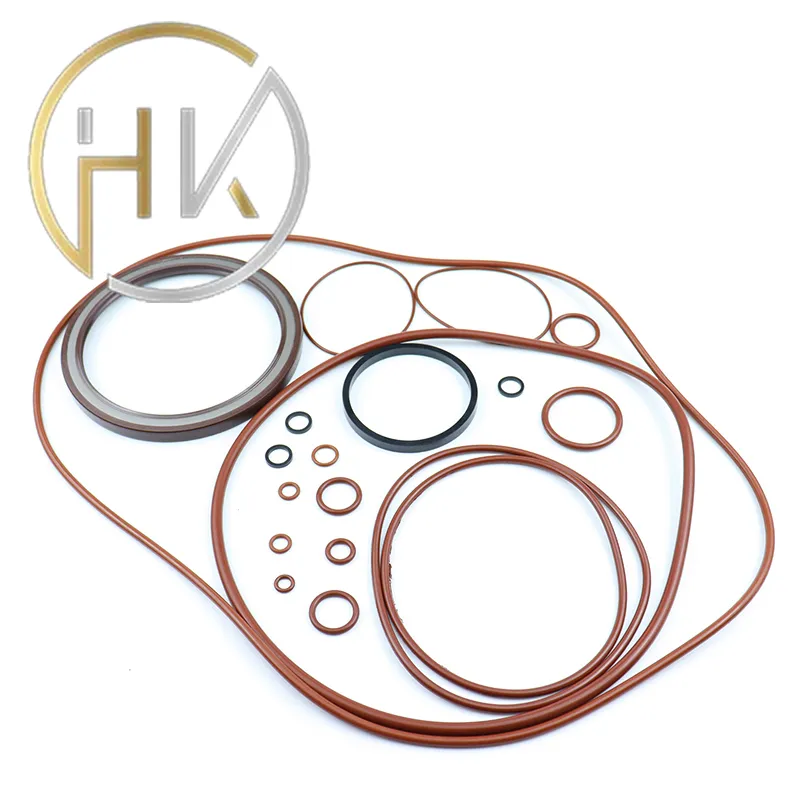

A seal kit consists of various sealing components that are designed to fit specific models of hydraulic or pneumatic cylinders. These kits usually contain O-rings, piston seals, rod seals, wear rings, backup rings, and other sealing elements. Each component serves a unique purpose, working together to create a tight seal, preventing leaks and keeping contaminants out of the system.

Types of Seals in a Seal Kit

1. O-Rings O-rings are circular rubber seals that fit into a groove to prevent fluid or air leaks. They are one of the most commonly used seals in both hydraulic and pneumatic applications due to their simple design and effective sealing properties.

2. Piston Seals These seals are located between the piston and the cylinder wall, responsible for containing the fluid pressure needed to operate the system. They are designed to withstand high pressures and provide a tight seal regardless of temperature changes.

3. Rod Seals Rod seals are used in dynamic applications where the rod moves in and out of the cylinder. These seals must cope with friction, pressure, and contamination while ensuring a reliable seal.

4. Wear Rings Wear rings are designed to minimize wear on the cylinder bore and increase the longevity of the seals. They help guide the movement of the piston and maintain alignment.

seal kit for cylinder

5. Backup Rings These rings are used in conjunction with O-rings to prevent extrusion under high pressure, providing added support to the main sealing components.

Importance of Seal Kits

The importance of seal kits cannot be overstated. Properly functioning seals are critical in maintaining the integrity of hydraulic and pneumatic systems. They prevent fluid leaks, which can lead to loss of efficiency and potentially catastrophic system failures. Regular maintenance, which includes replacing worn or damaged seals, can prolong the life of cylinders and enhance the performance of the entire system.

Additionally, using high-quality seal kits can improve operational safety by reducing the risk of leaks that may lead to hazardous conditions, especially in industrial environments. They also contribute to cost savings by minimizing downtime and the need for extensive repairs.

Choosing the Right Seal Kit

When selecting a seal kit for a cylinder, it is vital to consider several factors

- Compatibility Ensure that the seal kit matches the specific make and model of the cylinder. - Material Different applications require different seal materials, such as nitrile, polyurethane, or fluorocarbon, depending on the operating environment. - Operating Conditions Consider the temperature, pressure, and types of fluids involved when choosing a seal kit.

In conclusion, a seal kit for a cylinder is an essential component in ensuring the reliability and efficiency of hydraulic and pneumatic systems. Understanding the different types of seals included in these kits and their specific functions can help users maintain optimal performance and safety in their operations. By investing in quality seal kits and conducting regular maintenance, users can significantly enhance the lifespan and efficiency of their systems, leading to overall improved productivity and safety in their applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories