2 月 . 15, 2025 11:07 Back to list

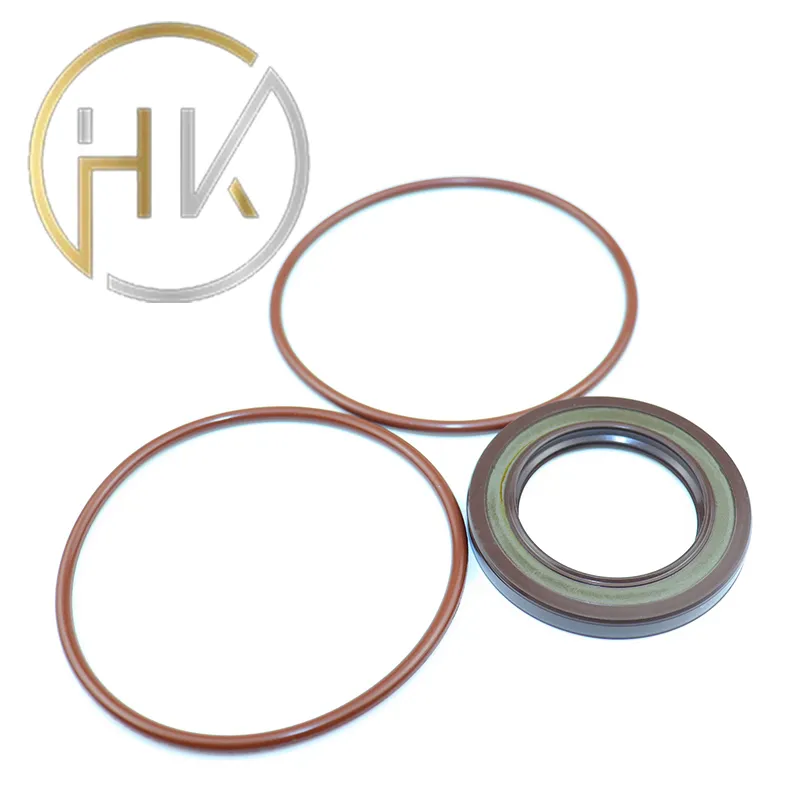

rotary shaft oil seals

Trustworthiness is built over time, particularly through transparent communication and post-sale support. Businesses crafting these oil seals earn client loyalty by providing detailed product documentation that includes installation guidelines, maintenance tips, and troubleshooting advice. Additionally, companies with robust quality assurance processes such as batch testing and client feedback loops demonstrate a commitment to product reliability and customer satisfaction. The versatility of rotary shaft oil seals extends across multiple fields—from automotive and aerospace to manufacturing and marine applications. In automotive engines, these seals are crucial for keeping oil within the engine, preventing leaks that can cause engine damage or reduced efficiency. In the aerospace sector, they ensure the integrity of hydraulic systems, which is critical for safe operations. Their use in manufacturing machines helps in maintaining lubricant levels, ensuring smooth and continuous operation, thus minimizing downtime and maintenance costs. A practical tip for maximizing the lifespan of rotary shaft oil seals is regular inspection and maintenance. Frequent checks for signs of wear, such as hardening, cracking, or grooving, can preempt more severe issues. Using the right installation tools and methods can prevent initial damage, thereby prolonging the effective life cycle of the seals. For industries looking to optimize productivity and machinery uptime, investing in high-quality rotary shaft oil seals and adhering to a preventive maintenance schedule is a cost-effective strategy. In closing, the understated yet vital role of rotary shaft oil seals in machinery cannot be overstated. Their correct selection, installation, and maintenance are crucial for efficient machine operation and longevity. By understanding and implementing the knowledge shared by experts in the field, businesses can ensure reliability and excellence in their mechanical processes, ultimately leading to greater operational successes and enhanced economic outcomes.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories