10 月 . 31, 2024 07:16 Back to list

rotary oil seals

Understanding Rotary Oil Seals An Overview

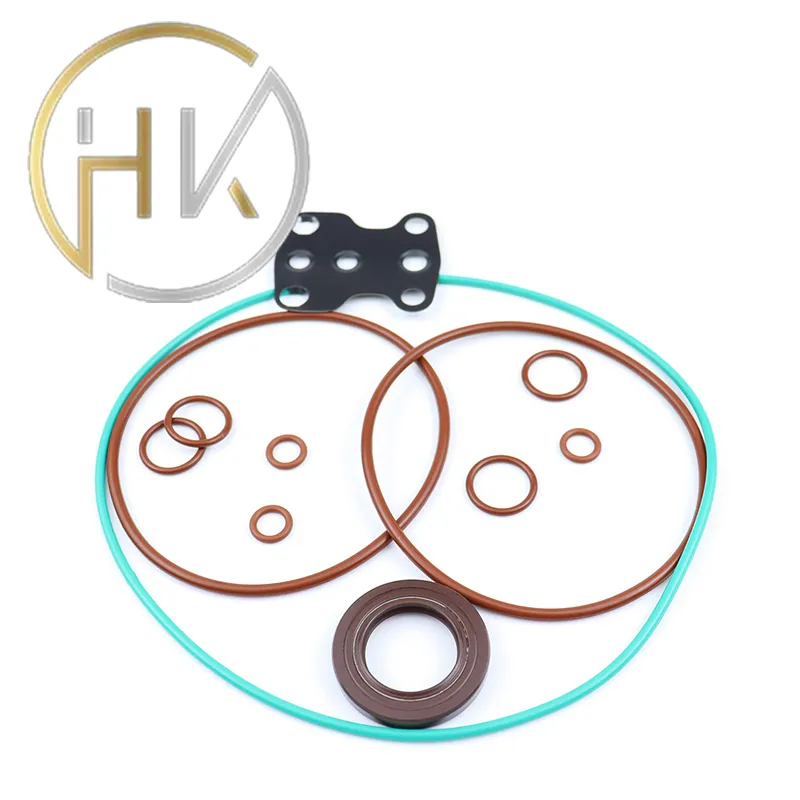

Rotary oil seals, also known as radial shaft seals, are critical components used in various mechanical applications, especially in machinery where rotating shafts are involved. Their primary function is to prevent the leakage of fluids, such as oils and lubricants, from a rotating component, while also keeping contaminants out.

Design and Composition

Rotary oil seals typically consist of a circular elastomeric material that fits snugly around the shaft. The design often features a lip or sealing edge that makes contact with the shaft, creating a barrier that minimizes leakage. The materials used for the seal can range from rubber compounds, like nitrile and silicone, to more advanced materials like fluorocarbon and polyurethane, depending on the operating conditions, such as temperature, pressure, and the type of fluid being sealed.

Applications

Rotary oil seals are widely used across various industries, including automotive, aerospace, manufacturing, and marine applications. In automotive settings, they play a crucial role in engines, gearboxes, and wheel hubs, ensuring that lubrication is maintained and that dirt and moisture do not intrude into these critical components. In industrial machinery, rotary oil seals help prolong the life of equipment by preventing premature wear caused by oil leaks and contamination.

rotary oil seals

Importance of Proper Installation

The efficiency of rotary oil seals greatly depends on proper installation. Misalignment, improper fitting, or excessive force can lead to seal damage or premature failure. It is essential to ensure that the shaft surface is smooth and clean before installation and that the seal is positioned correctly to avoid operational issues such as leaks or increased friction.

Maintenance and Replacement

Regular maintenance checks can help identify any wear or degradation in rotary oil seals. Signs of failure may include leaks or visible damage to the seal. Timely replacement is crucial, as a non-functioning seal can lead to significant fluid loss, increased operational costs, and potential equipment failure.

Conclusion

In summary, rotary oil seals are indispensable in ensuring the smooth operation and longevity of rotating machinery. Their ability to prevent leaks and protect components from contaminants makes them vital in numerous applications. Understanding their design, correct installation, and maintenance practices can significantly enhance equipment performance and durability, making rotary oil seals a key element in effective mechanical engineering and system design.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories