10 月 . 05, 2024 06:52 Back to list

How to Change Wiper Seal on Hydraulic Cylinder for Optimal Performance

Replacing Wiper Seal on Hydraulic Cylinder A Step-by-Step Guide

Hydraulic cylinders are essential components in many machinery and equipment, providing the necessary force and movement through hydraulic pressure. One critical component of a hydraulic cylinder is the wiper seal, which prevents dirt and debris from entering the cylinder while ensuring the hydraulic fluid remains contained. Over time, wiper seals can wear out or become damaged, leading to leaks and performance issues. If you find yourself in need of replacing the wiper seal on a hydraulic cylinder, follow this comprehensive guide to ensure a successful replacement.

Tools and Materials Needed

Before getting started, gather the necessary tools and materials - New wiper seal (ensure it’s the correct size for your cylinder) - Wrench set - Screwdrivers (flat and Phillips) - Seal puller or hook tool - Clean rags - Hydraulic fluid (if needed) - Safety goggles and gloves

Step 1 Safety First

Before you begin, ensure the hydraulic system is depressurized. Disconnect the power source to the machine, and relieve any remaining pressure in the cylinder by moving the rod in and out carefully. Always wear safety goggles and gloves to protect yourself from any hydraulic fluid.

Step 2 Disassemble the Cylinder

Using the appropriate wrenches, remove the cylinder from its mounting. Once removed, unscrew the end cap of the hydraulic cylinder to access the internal components. Be sure to keep track of any washers or O-rings as you disassemble.

Step 3 Remove the Old Wiper Seal

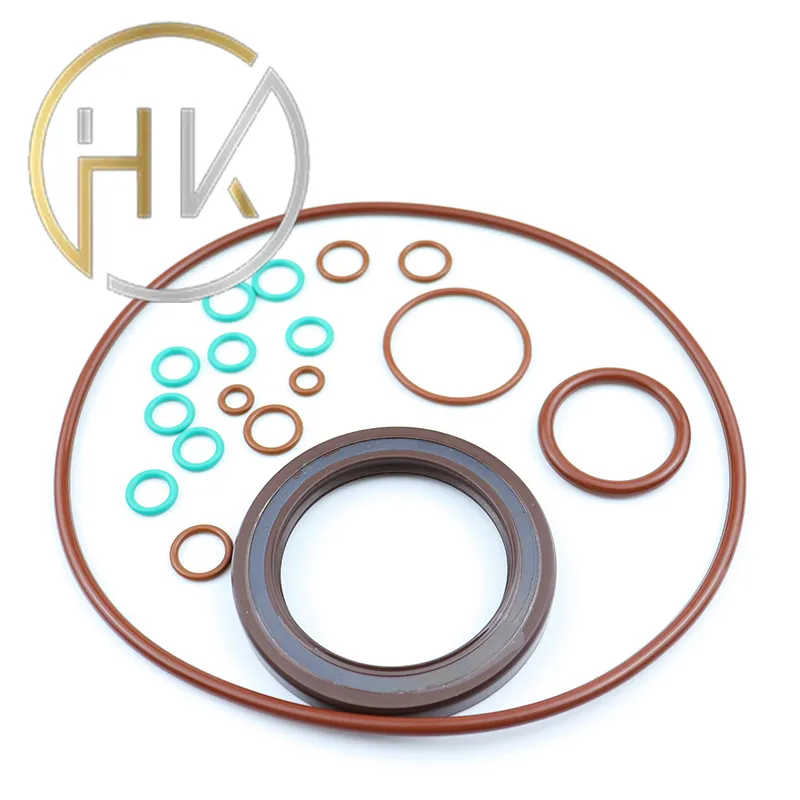

replacing wiper seal on hydraulic cylinder

Carefully inspect the old wiper seal. Using a seal puller or hooked tool, gently pry up the old seal from its groove. Take care not to damage the cylinder itself during this process. Clean the groove where the seal sits to ensure a proper fit for the new seal.

Step 4 Install the New Wiper Seal

Before installing the new wiper seal, inspect it for any defects and confirm it fits correctly. Lubricate the new seal lightly with hydraulic fluid to facilitate installation. Place the new seal into the groove, ensuring it sits evenly all around.

Step 5 Reassemble the Cylinder

With the new wiper seal in place, reattach the end cap securely. Make sure to replace any O-rings or washers you removed during disassembly. Reassemble the hydraulic cylinder to the machine, ensuring all connections are tight and secure.

Step 6 Testing the Cylinder

Once everything is reassembled, reconnect the power source and conduct a test run. Observe the cylinder for any leaks and verify smooth operation. If everything functions correctly, you have successfully replaced the wiper seal.

Conclusion

Replacing the wiper seal on a hydraulic cylinder can extend the lifespan of your equipment and ensure optimal performance. By following these steps meticulously, you can confidently tackle this task and maintain the efficiency of your hydraulic systems.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories