2 月 . 13, 2025 02:39 Back to list

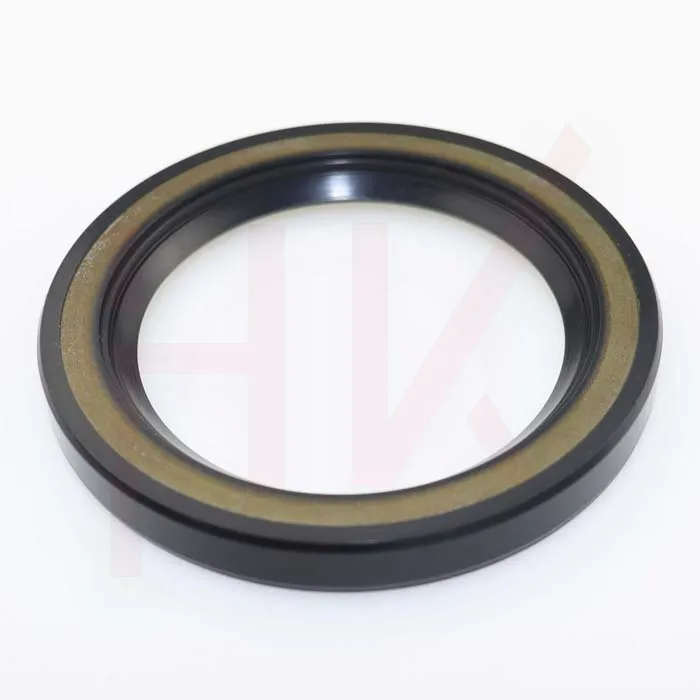

agricultural seals

Selecting the correct seals is an area where expertise truly makes a difference. Understanding material compatibility—be it nitrile, Viton, or polyurethane—is vital to ensure that new seals will perform optimally under expected temperature and pressure conditions. Consulting with seal manufacturers or distributors can provide valuable insights into the most suitable products for your specific application. Installation of the new seals must be done with precision to prevent future failures. Lubricating the seals before installation can ease the process and reduce friction, which enhances longevity. Gently place and align seals in their respective grooves, ensuring that they sit evenly without twisting or distortion. Once installed, reassemble the cylinder with care, paying close attention to the torque specifications for fasteners to avoid over-tightening and potential damage. Testing is the final phase. Reconnect the hydraulic system and gradually restore pressure, checking for any leaks or performance issues. A successful seal replacement should result in a leak-free operation with restored cylinder efficiency. Ongoing maintenance, including routine inspections and timely replacements, will further guarantee the hydraulic system's optimal performance. Incorporating trustworthiness, working with reputable seal suppliers and leveraging expert consultations reinforce the reliability of your maintenance efforts. A partnership with accredited professionals can ensure access to high-quality materials, enhancing the durability and efficiency of your hydraulic systems. In summary, replacing seals in hydraulic cylinders is a meticulous process that requires expertise and attention to detail. Proper diagnosis, careful removal and installation of seals, and reliance on quality products ensure the hydraulic system operates efficiently and reliably, safeguarding your investment and extending the lifespan of your machinery.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories