10 月 . 11, 2024 16:20 Back to list

Understanding the Function and Benefits of Radial Oil Seals in Machinery

The Importance of Radial Oil Seals in Mechanical Systems

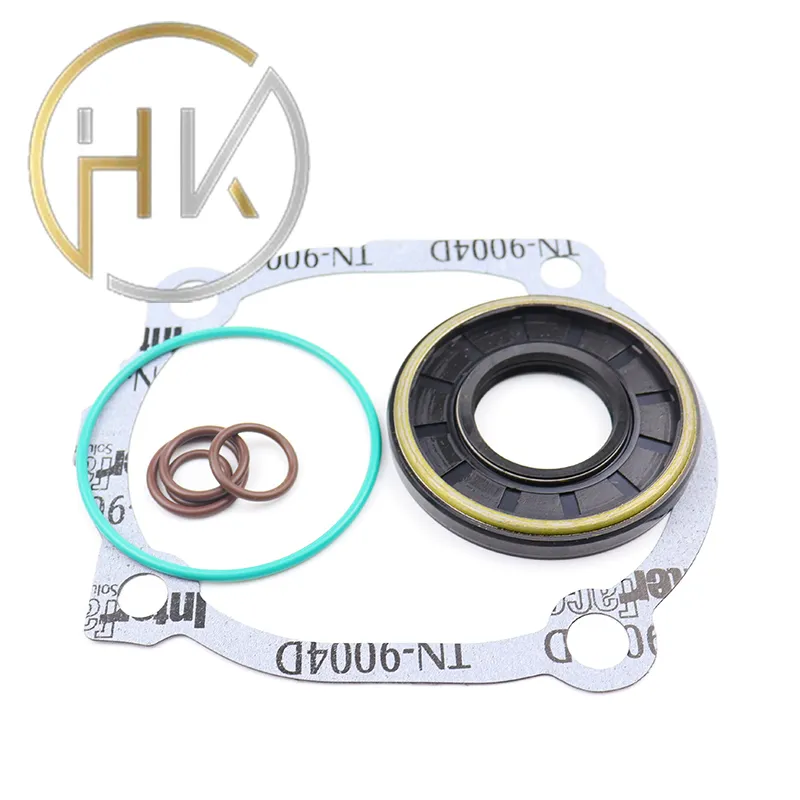

Radial oil seals, often referred to as rotary seals, play a critical role in a multitude of mechanical systems across various industries. These seals are specifically designed to retain lubricants and prevent contamination from external particles, ensuring the smooth operation of machinery. Their applications range from automotive components to industrial equipment, illustrating their versatility and necessity.

At the heart of a radial oil seal’s function is its ability to create a reliable barrier against liquids and contaminants. Typically made from rubber or synthetic materials, radial oil seals come in various sizes and configurations to suit different applications. The most common design features a flexible lip that presses against the shaft or bore, forming a tight seal that minimizes leakage.

One of the primary functions of these seals is to retain oil within gearboxes, engines, and hydraulic systems. By preventing oil from escaping, radial seals help maintain the necessary lubrication for moving parts. This is crucial because insufficient lubrication can lead to increased friction, overheating, and ultimately, mechanical failure. Therefore, the integrity of radial oil seals is vital for the longevity and performance of machinery.

Moreover, in addition to oil retention, radial seals also serve to exclude dirt, dust, and moisture from entering mechanical systems. Contamination can significantly impair the performance of machinery, as it may lead to wear and tear on components. Dust and dirt particles can act like abrasives, increasing the likelihood of system failures and necessitating costly repairs. By effectively sealing the interfaces between moving parts, radial oil seals safeguard against these detrimental elements.

radial oil seal

The design of a radial oil seal is critical for its performance. Manufacturers spend significant time engineering seals that can withstand various pressures, temperatures, and chemical environments. For instance, seals designed for automotive applications must endure high temperatures and fluctuating pressures, while those used in hydraulic systems may face aggressive fluids. The choice of material, lip design, and construction method can all influence the seal's effectiveness.

Installation is another critical aspect of radial oil seals. Proper installation is essential to maintain their sealing capability. Misalignment, incorrect sizing, or improper handling during installation can lead to premature seal failure. Therefore, it is recommended that seals are installed following the manufacturer’s guidelines, often using specialized tools to avoid damaging the seal during the process.

Despite their relatively simple appearance, the technology behind radial oil seals continues to evolve. Innovations in materials and design are enabling manufacturers to produce seals that offer enhanced performance and durability. The advent of advanced elastomers and sealing technologies has led to products that can operate in harsher environments while providing superior sealing capabilities.

In conclusion, radial oil seals are a fundamental component in many mechanical systems, ensuring the retention of lubricants and protection against contamination. Their ability to enhance the longevity and reliability of machinery cannot be overstated. As industries continue to demand higher performance and efficiency from their equipment, the development of more robust and effective radial oil seals will remain vital. Whether in automotive, aerospace, or industrial applications, these seals will continue to play an indispensable role in the mechanics of power transmission, making them a focal point in the maintenance and advancement of modern technologies. When selecting and maintaining radial oil seals, one must recognize their significance and the immense impact they have on the overall performance and durability of machinery.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories