10 月 . 19, 2024 09:31 Back to list

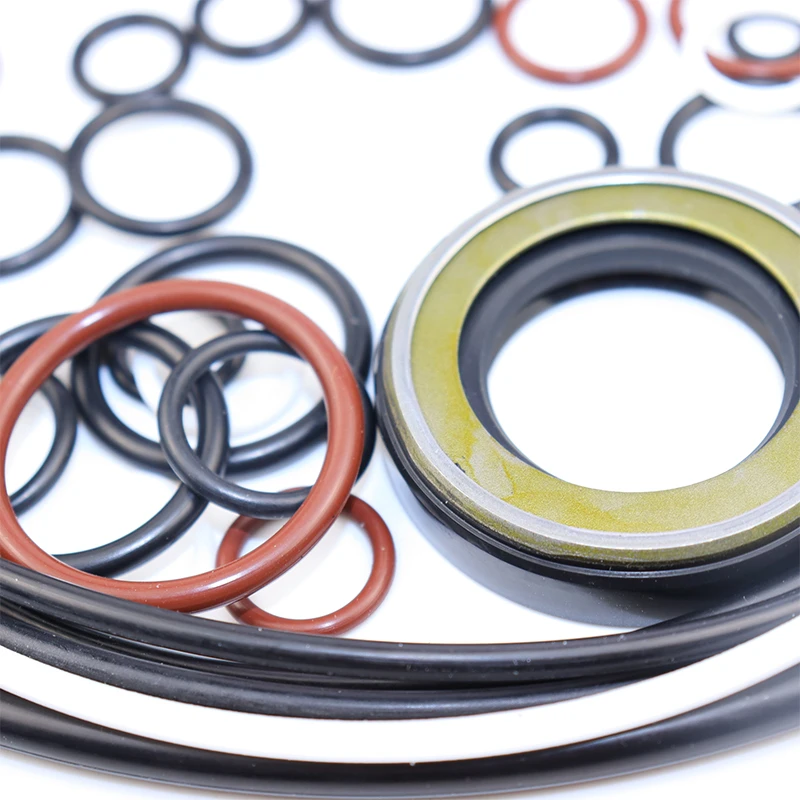

pu wiper seal

Understanding PU Wiper Seals Importance and Applications

In the world of industrial machinery and automotive engineering, maintaining efficiency and reliability often comes down to the smallest components. One such overlooked yet crucial component is the wiper seal, specifically the polyurethane (PU) wiper seal. These seals play an essential role in ensuring the smooth operation of various machines and vehicles by preventing leakage of fluids and contaminants. This article will delve into the characteristics, advantages, and applications of PU wiper seals to highlight their significance in different industries.

What is a PU Wiper Seal?

A PU wiper seal is a type of sealing element primarily made from polyurethane, a versatile polymer known for its durability and elasticity. Wiper seals are designed to prevent dirt, dust, and other contaminants from entering hydraulic systems, ensuring the optimal functionality of equipment. They are typically used in conjunction with other seals to create a comprehensive sealing system that protects critical components such as pistons and rods.

Characteristics of PU Wiper Seals

1. Durability One of the most significant advantages of PU wiper seals is their exceptional durability. Polyurethane is resistant to abrasion, wear, and tear, making it ideal for applications where seals are exposed to harsh working conditions.

2. Elasticity PU seals provide excellent elasticity, allowing them to maintain a tight seal even when subjected to movement and pressure changes. This elasticity helps in reducing the risk of leaks, thus protecting the internal components of machines.

3. Chemical Resistance Polyurethane exhibits good resistance to a wide range of chemicals, oils, and solvents. This characteristic is crucial in industrial applications where hydraulic fluids may be present.

4. Temperature Tolerance PU wiper seals can operate effectively in a broader range of temperatures compared to other materials. This temperature tolerance makes them suitable for varied environments, from extreme cold to high heat scenarios.

Advantages of PU Wiper Seals

1. Maintenance Reduction By effectively preventing contamination, PU wiper seals help in prolonging the life of hydraulic systems. This means less frequent maintenance and repairs, resulting in cost savings for businesses.

pu wiper seal

2. Enhanced Performance With a proper sealing system in place, machinery can operate at higher levels of efficiency. This optimal performance translates into improved productivity and better overall outcomes.

3. Versatility PU wiper seals can be manufactured in various shapes and sizes, making them suitable for a wide array of applications. They can be tailored to meet specific requirements, ensuring a perfect fit for diverse machinery.

4. Eco-Friendly Options Some manufacturers now offer environmentally friendly polyurethane formulations that further enhance the appeal of PU wiper seals. These eco-friendly options cater to industries pushing for sustainability and reduced environmental impact.

Applications of PU Wiper Seals

The applications of PU wiper seals are vast. They are commonly found in

- Hydraulic and Pneumatic Systems In industrial machinery, PU wiper seals are vital for preventing the ingress of dirt and moisture into hydraulic cylinders, ensuring optimal performance.

- Automotive Industry In vehicles, these seals are used to protect critical components of steering systems, suspension systems, and shock absorbers, where they effectively keep contaminants out and reduce wear.

- Construction Equipment Heavy machinery that operates under tough environmental conditions significantly benefits from PU wiper seals due to their robust properties and ability to withstand hydraulic pressures.

- Agricultural Equipment Tractors and harvesters often utilize these seals to maintain the integrity of hydraulic and pneumatic systems, ensuring efficient operation during farming activities.

Conclusion

In conclusion, PU wiper seals are a vital component in maintaining the functionality and longevity of various machinery across multiple industries. Their unique properties, including durability, elasticity, and resistance to environmental factors, make them an ideal choice for sealing applications. By understanding their importance and applications, businesses can better appreciate the role of these small yet significant components in enhancing efficiency and reducing overall operational costs. To ensure optimal performance, it is essential to select the right type of wiper seal and maintain it effectively, thereby guaranteeing the smooth operation of machinery in the long run.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories