10 月 . 12, 2024 09:44 Back to list

pump seal kit

Understanding Pump Seal Kits Essential for Optimal Performance

A pump seal kit plays a crucial role in ensuring the efficient operation of various types of pumps used across industries. Whether in water treatment facilities, chemical manufacturing, or oil and gas sectors, pumps are vital for transporting fluids. However, the performance of pumps can be significantly affected by the condition and functionality of their seals. This is where pump seal kits come into play.

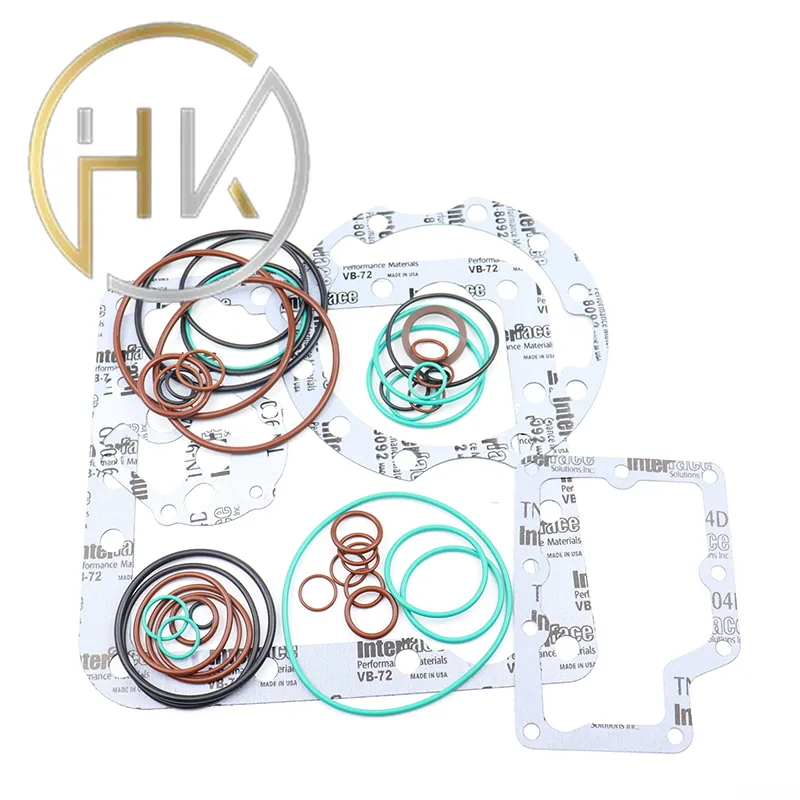

Pump seal kits typically contain all the necessary components required to repair or replace worn-out seals in a pump. These kits generally include mechanical seals, O-rings, gaskets, and other sealing components tailored for specific pump models. Ensuring that the seals are regularly maintained or replaced as part of routine maintenance can prevent leaks, reduce downtime, and enhance overall efficiency.

One of the primary advantages of using a pump seal kit is the cost-effectiveness it offers

. Instead of purchasing individual components separately, seal kits provide a comprehensive solution that can save time and money. They are designed to ensure compatibility and reliability, eliminating the guesswork associated with selecting the right components.pump seal kit

Moreover, the use of high-quality seal kits contributes to the longevity of the pump. Seals are the first line of defense against leaks, which can lead to operational inefficiencies, environmental hazards, and costly repairs. By investing in a quality pump seal kit, operators can ensure their pumps function optimally, minimizing the risk of failure.

It is essential to select the appropriate seal kit for your specific pump model and application. Different environments may require different materials; for example, pumps handling abrasive liquids often benefit from more durable materials like ceramic or carbon models. Additionally, environmental factors such as temperature and pressure also play a significant role in determining the best seal kit material.

Regular inspection and timely replacement of pump seals are vital for maintaining system integrity. Signs of a failing pump seal may include unusual noise, visible leaks, or a drop in pump performance. By promptly addressing these issues with a quality seal kit, operators can maintain productivity and ensure the smooth operation of their systems.

In conclusion, pump seal kits are indispensable for anyone relying on pumps in their operations. They provide a comprehensive, cost-effective, and essential solution for maintaining optimal pump performance, ensuring reliability and efficiency while extending the life of the pump. Understanding and utilizing these kits not only safeguards investments but also contributes to smoother, uninterrupted operations across various industries.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories