8 月 . 31, 2024 14:51 Back to list

pump seal kit

Understanding Pump Seal Kits Essential Components for Optimal Performance

Pump seal kits are integral to the efficient operation of pumps across various industries. These kits are designed to ensure that pumps function reliably by preventing leaks and maintaining pressure. Given the critical role that pumps play in numerous applications, from water treatment to chemical processing, understanding the components and benefits of pump seal kits is essential for engineers, technicians, and maintenance personnel.

What is a Pump Seal Kit?

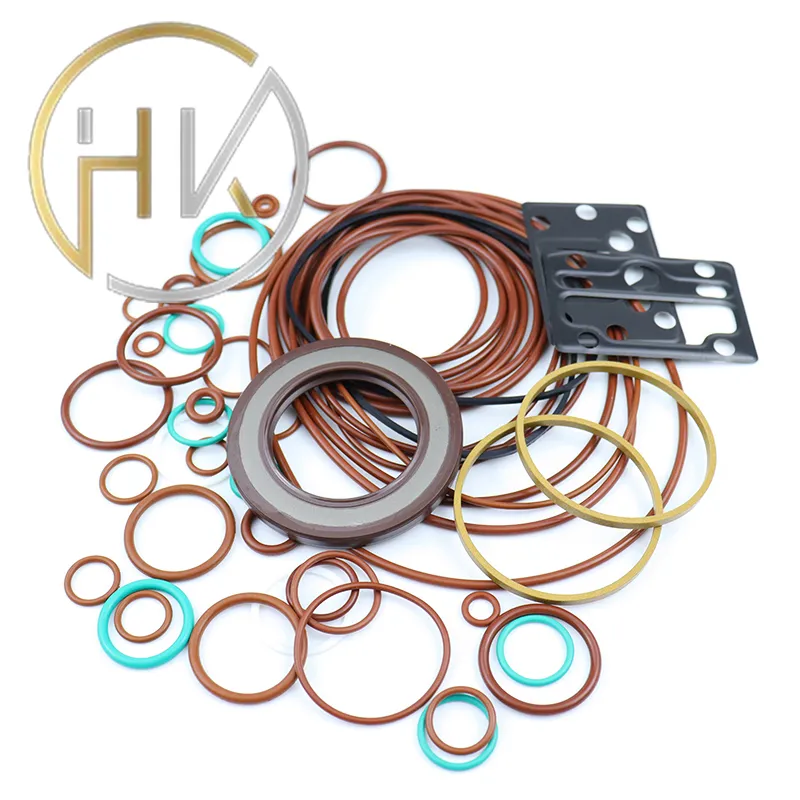

A pump seal kit typically contains various elements designed to replace worn or broken seals in a pump. These components often include O-rings, gaskets, mechanical seals, and secondary seals. Each part is specifically engineered to fit a particular pump model, ensuring that replacements are seamless and effective.

The primary function of these seals is to prevent the leakage of fluids, which is crucial for both safety and efficiency. A leaky pump can lead to a myriad of problems, including environmental contamination, increased operational costs, and equipment damage. Therefore, regularly inspecting and replacing these seals as part of preventive maintenance is vital.

Key Components of Pump Seal Kits

1. O-Rings Made from various materials, O-rings create a tight seal in static and dynamic applications. Their elastic nature allows them to compress and expand, making them suitable for a range of temperatures and pressures.

2. Mechanical Seals Often used in centrifugal pumps, mechanical seals consist of two flat surfaces that must be perfectly aligned. They provide a robust barrier against leakage and are designed to withstand high pressures, making them ideal for various industrial applications.

3. Gaskets Gaskets are used to create a seal between two surfaces and come in various materials, including rubber, silicone, and even metal. They are essential for ensuring that connections between components remain leak-free.

pump seal kit

4. Secondary Seals These are additional layers of seals that provide extra protection against leaks. They are particularly important in high-pressure environments where the risk of fluid escape is heightened.

Benefits of Using Pump Seal Kits

1. Enhanced Reliability Regularly replacing seals using a pump seal kit significantly improves the reliability of pumps, reducing the likelihood of unexpected failures.

2. Cost-Effectiveness Maintaining pumps with seal kits can save money in the long run. Preventing leaks minimizes waste and potential damage to the surroundings or other equipment, which can be costly to rectify.

3. Improved Safety Leaks can pose serious safety hazards, particularly in industries dealing with hazardous materials. Using proper seal kits helps mitigate these risks, ensuring a safer work environment.

4. Simplified Maintenance Using comprehensive pump seal kits makes the maintenance process easier for technicians. All necessary components are included, simplifying the replacement process.

Conclusion

In conclusion, pump seal kits are vital for the proper functioning and maintenance of pumps in various industries. They not only enhance the reliability and efficiency of pumps but also ensure safety and cost-effectiveness. Understanding the components and benefits of pump seal kits can empower industry professionals to make informed decisions regarding their maintenance strategies. Therefore, investing in quality seal kits is not just a necessity; it’s a strategic move towards achieving optimal performance in fluid management systems.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories