3 月 . 05, 2025 03:18 Back to list

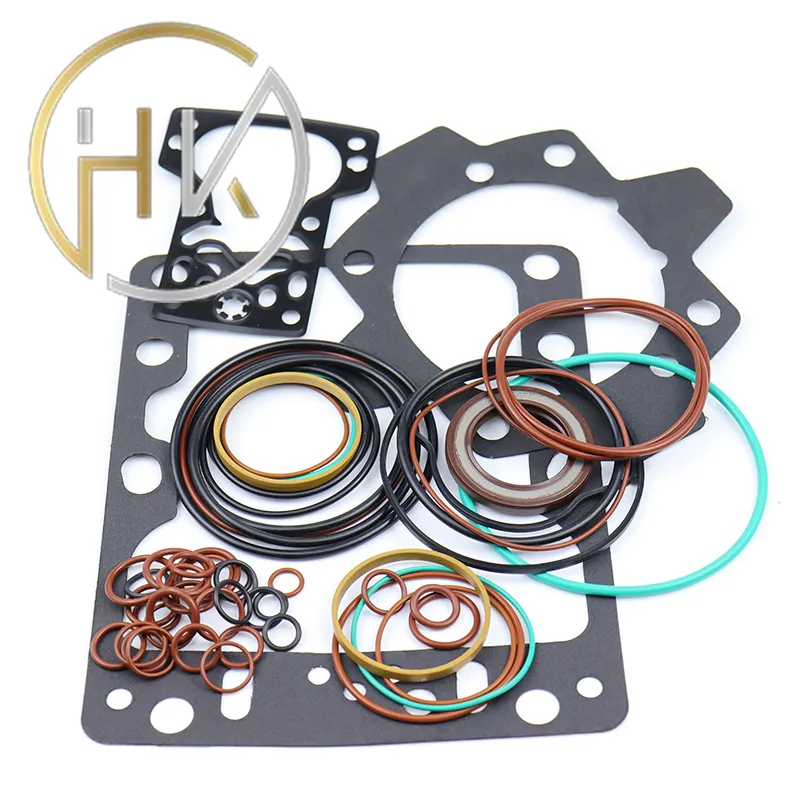

wiper seals

Real-world experiences underscore the effectiveness and reliability of PTFE wiper seals. For instance, in the hydraulics sector, operators have documented how PTFE wiper seals enhance system performance by reducing wear and tear on cylinders and pistons. This reduction not only prolongs equipment life but also minimizes downtime, optimizing productivity. Similarly, in the oil and gas industry, PTFE wiper seals are valued for their durability in extreme temperatures and their superior sealing capabilities, which prevent hazardous leaks, thus upholding safety and maintaining operational standards. The unrivaled performance of PTFE wiper seals can also be attributed to their exceptional adaptability in design. Engineers appreciate the material's capacity to withstand drastic temperature shifts, from sub-zero levels to soaring heat, without losing integrity. This adaptability allows for the seamless integration of PTFE wiper seals in diverse machinery, further showcasing their authoritative presence in seal technology. Moreover, PTFE wiper seals offer a significant advantage with their minimal maintenance requirements. Their low friction coefficient diminishes the need for frequent lubrication, which not only reduces maintenance costs but also limits the environmental impact associated with oil and grease disposal. This aspect appeals to companies aiming to achieve sustainability goals and reduce their carbon footprint. The positioning of PTFE wiper seals as a trusted industrial solution is fortified by continuous innovation and research. Leading manufacturers are perpetually engaged in research endeavours to enhance the inherent qualities of PTFE, tailoring it for emerging challenges in new industrial applications. Their commitment to maintaining the highest standards of quality and performance keeps PTFE wiper seals at the forefront of innovation in sealing technology. In conclusion, the multifaceted advantages of PTFE wiper seals establish them as a cornerstone for any application requiring reliable sealing solutions. Their unparalleled heat resistance, chemical inertness, and tribological properties, combined with the ability to perform in a wide spectrum of industrial applications, assert their position as an authoritative, credible choice for engineers and manufacturers worldwide. Businesses seeking to enhance their machinery's efficiency can trust in PTFE wiper seals to deliver superior performance, backed by decades of expertise and authoritative practices in sealing technology.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories