3 月 . 05, 2025 02:12 Back to list

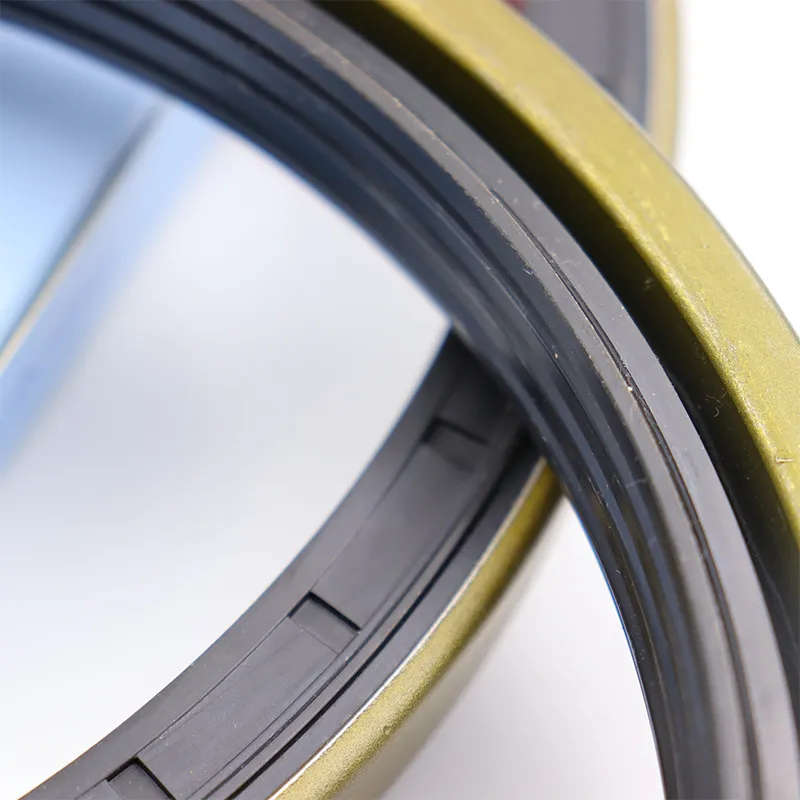

wiper seals

When it comes to installation, the piston wiper seal simplifies the process compared to its more complex counterparts. Its ease of installation reduces downtime and minimizes the room for error, solidifying its role as a go-to solution for engineers and technicians. Properly installed piston wiper seals can result in significant reductions in maintenance costs over the lifetime of the equipment, representing substantial cost savings and enhanced dependability. Moreover, sustainable engineering practices have taken a forefront in modern industrial settings. Piston wiper seals not only support operational sustainability by improving lifecycle performance but are also made from recyclable materials. This environmentally conscious approach aligns with growing global initiatives focused on reducing industrial carbon footprints, making the piston wiper seal not only a product of technical prowess but also of ethical engineering. In practical experience, the real value of piston wiper seals is showcased through case studies where industries report a marked improvement in the efficiency of hydraulic systems following their implementation. Feedback from field engineers consistently highlights the reduction in unexpected downtime and better system responsiveness. These improvements correlate directly with the operational success of industries relying on heavy-duty machinery operating in challenging environments. In conclusion, the piston wiper seal represents not just a component but a solution to a myriad of challenges faced in hydraulic and pneumatic applications. By excelling in durability, application versatility, and environmental consideration, piston wiper seals affirm their status as a critical ally in any system requiring robust, lasting sealing solutions. Their integration into engineering solutions epitomizes the synthesis of specialized expertise and practical innovation, fostering an industry standard that prioritizes performance, sustainability, and reliability.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories