2 月 . 10, 2025 11:25 Back to list

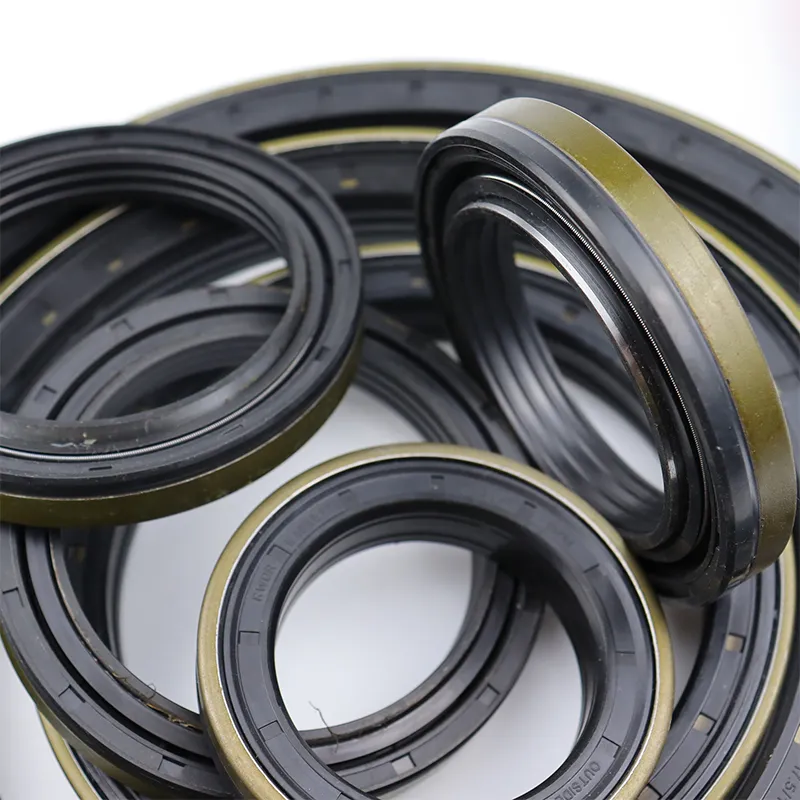

oil seal tcv

Experience with TCV oil seals reveals their unmatched capability in providing a robust barrier against leakage. In practical applications, maintenance engineers have noted a significant decline in unscheduled machine downtimes post-installation of TCV oil seals. The seals' resilience in thermal cycling conditions means fewer replacements and, ultimately, reduced operational costs. This reliability has been echoed by several mechanical and maintenance engineers who attest to measurable improvements in machinery efficiency. Trustworthiness is enhanced by transparency in manufacturing processes and product authenticity. Companies manufacturing TCV oil seals often provide detailed specification sheets and material safety data sheets (MSDS), reflecting a commitment to transparency and customer information. They also offer extensive warranty and testing data, reinforcing customer confidence in the product’s longevity and effectiveness. To sum up, TCV oil seals are not just a component but a testament to engineering precision, dynamic application, and stringent quality assurance that ensure machinery operates at its peak for longer, with minimal maintenance. Their development encapsulates cutting-edge technology and deep-seated industry knowledge making them the ideal choice for industries aiming to enhance operational efficacy and reliability. Whether in high-speed automobiles, high-tech aerospace components, or rugged heavy machinery, the oil seal TCV’s role is critical, making it a crucial investment towards sustaining machine longevity and performance.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories