10 月 . 30, 2024 18:21 Back to list

oil seal tcv

Understanding Oil Seal TCV An Essential Component in Mechanical Systems

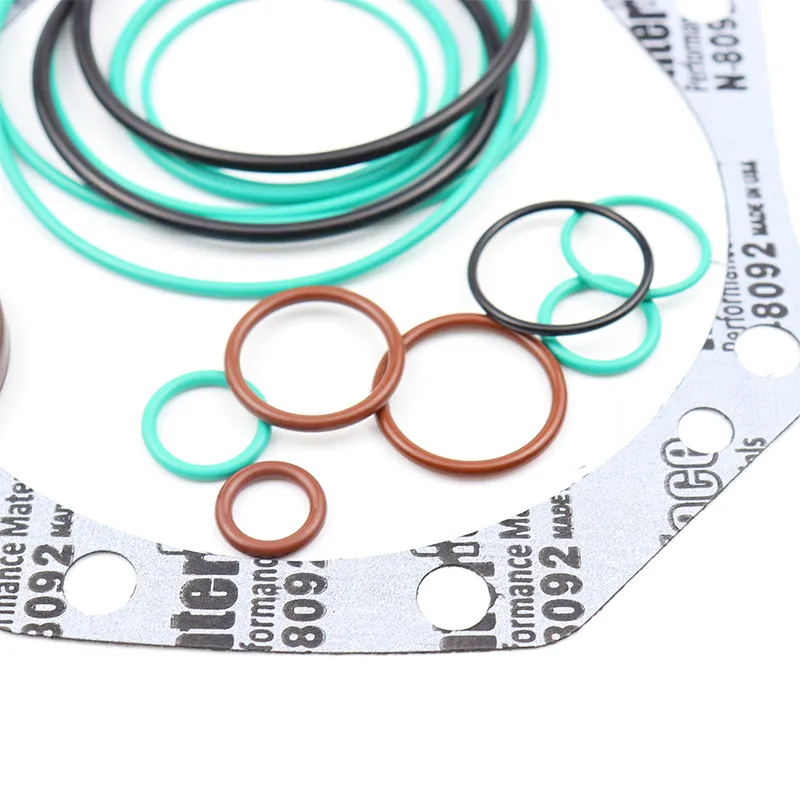

In the realm of mechanical engineering, the importance of sealing solutions cannot be overstated. Among these, the oil seal, often referred to as a TCV (TCV stands for Twin Contact V-ring), plays a crucial role in maintaining the integrity and efficiency of various machinery and automotive applications. This article delves into the significance, functionality, and applications of oil seal TCVs.

Understanding Oil Seal TCV An Essential Component in Mechanical Systems

One of the key advantages of TCVs is their adaptability to various operating conditions. They can withstand a range of temperatures and pressures, making them suitable for diverse environments—from high-speed automotive engines to heavy-duty industrial machinery. The materials used in TCV construction, such as rubber compounds and elastomers, are specifically chosen for their durability and resistance to wear and tear, ensuring a long service life.

oil seal tcv

Installation and maintenance of TCV oil seals are relatively straightforward, but they require precise alignment to function effectively. A faulty installation can lead to premature wear and failure of the seal, resulting in costly repairs. Therefore, proper training and adherence to manufacturer guidelines during installation are essential.

In terms of applications, oil seal TCVs are widely used in automotive sectors, including engines, transmissions, and differentials. Additionally, they are crucial in industrial applications such as pumps, gearboxes, and hydraulic systems. The automotive industry, in particular, emphasizes the need for reliable sealing solutions to meet stringent environmental regulations and enhance fuel efficiency.

In conclusion, the oil seal TCV is a vital component that ensures the smooth operation of machinery by preventing oil leakage and contamination ingress. Its dual-contact design offers significant advantages, making it a preferred choice across various sectors. Understanding its functionality and proper maintenance can significantly elevate the performance and longevity of mechanical systems. As technology advances, innovations in oil seal design will continue to enhance their reliability and effectiveness, further solidifying their importance in engineering applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories