1 月 . 06, 2025 19:20 Back to list

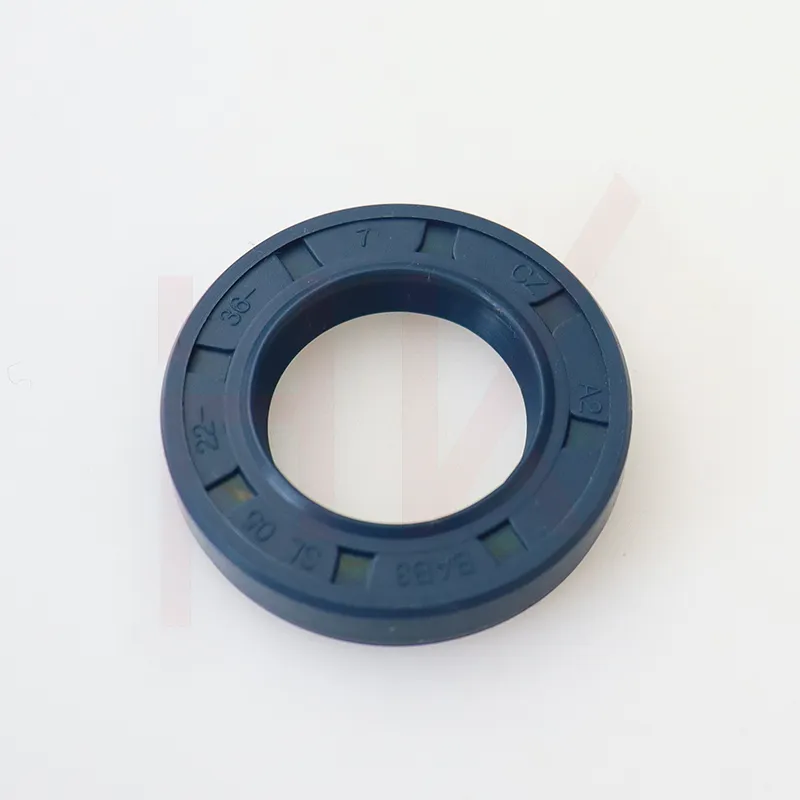

Standard High Pressure TCV Type Hydraulic Oil Seal

In the dynamic world of machinery and automotive industries, oil seals play a pivotal role in ensuring the longevity and efficiency of equipment. Selecting a reliable oil seal supplier can drastically influence the performance of your machinery. In this guide, we delve into the critical aspects that define an excellent oil seal supplier and why making an informed choice matters.

Experience in the field of manufacturing oil seals spells the difference between mediocrity and excellence. Established suppliers are equipped with the knowledge gained over years of service in the industry. Experience contributes to a comprehensive understanding of client needs and the ability to preemptively address potential issues. A supplier with a rich history in the field is more likely to have a robust quality assurance process, ensuring that the oil seals meet stringent industry standards and provide optimal functionality.

Expertise is another cornerstone of a distinguished oil seal supplier. Suppliers who specialize in oil seals often engage in ongoing research and development to improve the functionality and durability of their products. They may offer a range of oil seals tailored to specific applications, whether it be for automotive engines, industrial gearboxes, or hydraulic systems. Their expertise ensures they can guide you to the best type of oil seal for your particular application, understanding the nuances of material compatibility, pressure conditions, and environmental factors.

Authoritativeness is essential when evaluating an oil seal supplier. A reputable supplier will be recognized within the industry and have strong partnerships with other well-known entities. They may contribute to industry standards and participate in technical committees that push forward innovations in oil seal technology. This authoritative presence not only reinforces the quality of their products but also assures you that their solutions are based on the latest technological advancements and industry benchmarks.

oil seal supplier

Trustworthiness is the foundation of a successful partnership with an oil seal supplier. Transparency in dealings, consistency in quality, and the commitment to stand by their products are signs of a trustworthy partner. Suppliers who offer warranties and quick remediation in cases of defects or issues demonstrate their trust in their products and their dedication to customer satisfaction. Testimonials, case studies, and certifications can also be indicators of a supplier's reliability and commitment to excellence.

When it comes to selecting an oil seal supplier, thorough research and evaluation based on these core principles—experience, expertise, authoritativeness, and trustworthiness—are vital. Selecting a supplier that excels in these areas means more than just purchasing a component; it means entering a partnership that supports your operations through innovative, reliable, and efficient sealing solutions.

In the competitive arena where machinery reliability translates to operational success, the right oil seal supplier stands as an invaluable ally. Such a supplier not only provides high-quality products but also empowers you with the confidence that your equipment will perform optimally under demanding conditions. As industries continue to evolve, aligning with an oil seal supplier who exemplifies these four pillars is a strategic move towards sustained efficiency and growth.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories