2 月 . 10, 2025 10:35 Back to list

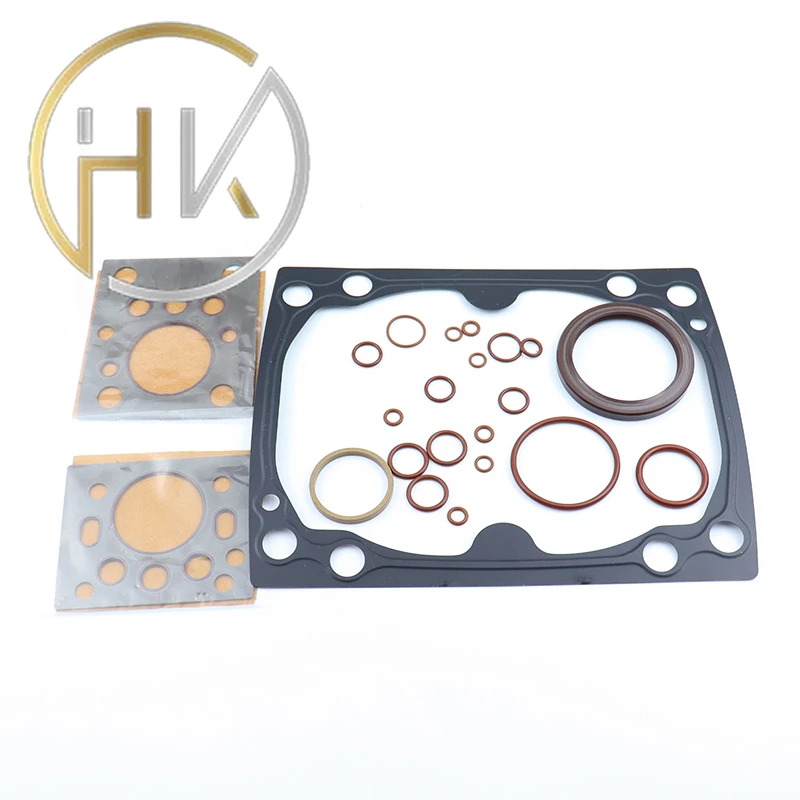

Standard High Pressure TCV Type Hydraulic Oil Seal

One authoritative point to note is the importance of the seal's design. A lip seal, for example, is more suitable for high-pressure applications, providing enhanced sealing capability through its flexible lip which maintains contact with the rotating shaft. Furthermore, double lip seals offer additional protection by incorporating a secondary lip to block contaminants from entering the system. Understanding the precise demands of your hydraulic system allows for informed decisions, thereby optimizing performance and longevity. Trust in oil seal performance is built over time and through rigorous testing. Leading manufacturers subject their seals to extensive trials to ensure they meet stringent standards. These include testing for durability, pressure resistance, and compatibility with different hydraulic fluids. A seal that passes these assessments not only meets industry standards but often exceeds customer expectations, ensuring reliability and enhancing trust in machinery performance. Incorporating this knowledge into maintenance practices is equally vital. Regular inspection and timely replacement of oil seals are crucial steps in preventive maintenance. Specialists emphasize the importance of checking for signs of wear, such as cracks or hardening of the sealing element. Implementing a routine maintenance schedule ensures that oil seals function optimally, preventing unexpected downtime. Ultimately, the choice of an oil-seal, grounded in expertise and experience, can transform your hydraulic system's reliability. By considering material, design, and maintenance practices, industries can optimize their operations, reduce costs, and enhance safety. Establishing trust in your hydraulic system begins with the humble yet mighty oil seal—an essential component that seals the system's promise of performance and longevity.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories