9 月 . 24, 2024 11:23 Back to list

Exploring Seals for Rotating Shafts in Machinery Applications

Understanding Oil Seals for Rotating Shafts A Critical Component in Machinery

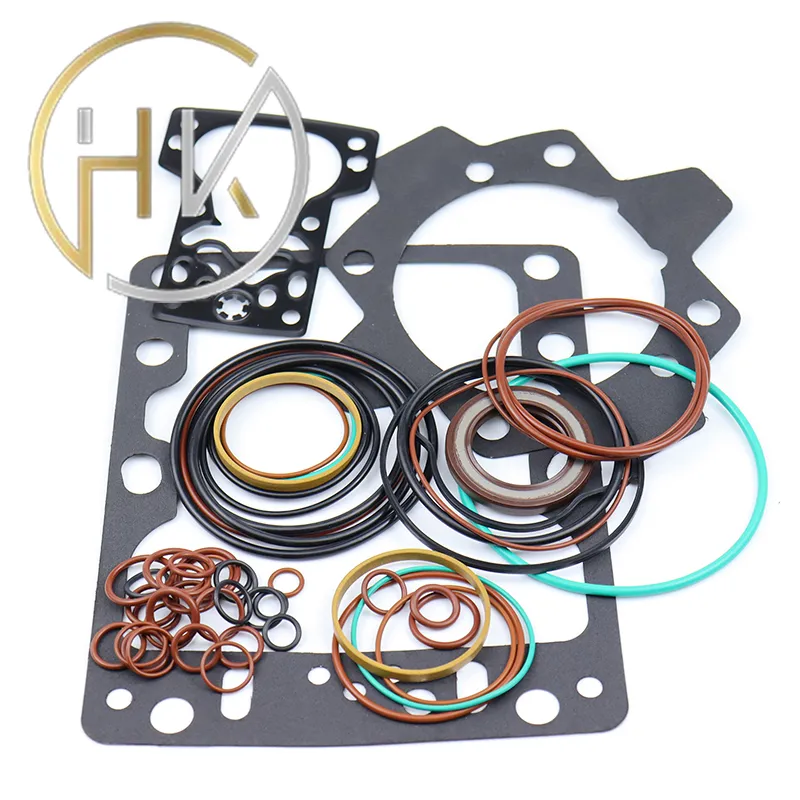

Oil seals, also known as grease seals, are integral components in various rotating machinery that require effective sealing solutions. They serve the crucial function of preventing lubricant leakage while also protecting against external contaminants such as dust, dirt, and moisture. Oil seals are commonly found in applications ranging from automotive engines to industrial machinery, ensuring that systems operate smoothly and efficiently.

What is an Oil Seal?

An oil seal is a type of mechanical seal that is specifically designed to retain oil or grease in a rotating shaft assembly. Typically made from elastomers such as rubber, nitrile, or silicone, these seals can come in various shapes and sizes suited to different applications. Their primary role is to maintain a barrier, thus preventing the loss of lubricants that are vital for reducing friction and wear in rotating parts.

Types of Oil Seals

Oil seals can be categorized based on their design and application. The most common types are

1. U-Cup Seals Shaped like a “U”, these seals are designed for higher pressure applications. They provide excellent sealing capabilities and are often used in hydraulic cylinders. 2. Lip Seals Features a flexible lip that makes contact with the rotating shaft, lip seals are the most widely used type of oil seal. They come in single-lip and double-lip configurations, enhancing their sealing effectiveness.

3. V-Rings These seals are mounted on the shaft and provide a barrier to contaminants while allowing for some axial movement.

Choosing the Right Oil Seal

oil seal for rotating shaft

Selecting the appropriate oil seal is vital for ensuring optimal performance and longevity of machinery. Several factors need to be considered during this process

- Operating Conditions The temperature, pressure, and speed of the rotating shaft determine the materials and design of the seal. - Chemical Compatibility The seal material must be compatible with the lubricants and any contaminants it may encounter to avoid degradation.

- Shaft Diameter Accurate measurements are essential, as even a minor variation can lead to seal failure.

- Installation Environment Consideration of the installation conditions, including the presence of contaminants or environmental elements, is crucial in selecting a suitable seal type.

Importance of Oil Seals

The importance of oil seals in rotating machinery cannot be overstated. They play a pivotal role in ensuring that lubricants remain where they are needed, thus reducing friction and preventing wear on moving parts. This contributes to the longevity and reliability of machinery, reduces maintenance costs, and enhances overall operational efficiency.

Moreover, failing to use the right oil seals can lead to catastrophic failures, which can result in expensive downtime and repair costs. Therefore, it is essential for manufacturers and equipment operators to understand the significance of these seals and invest in quality solutions.

Conclusion

In conclusion, oil seals are indispensable components of rotating shafts, serving to retain lubricants and protect against contaminants. Understanding the different types, their applications, and the factors influencing their selection is vital for anyone involved in machinery design, maintenance, or operation. By prioritizing the right oil seals, we can ensure the optimal performance and durability of mechanical systems in various industries.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories