3 月 . 07, 2025 07:11 Back to list

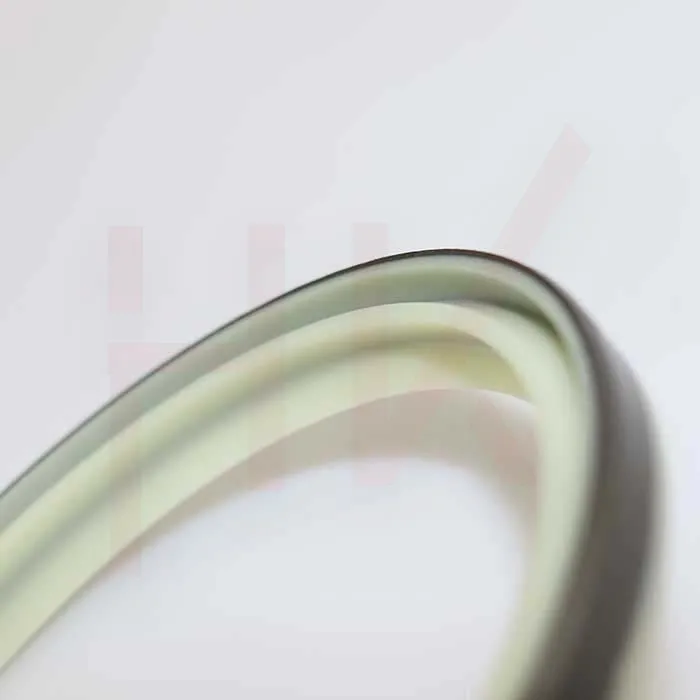

170×190×13 Tcv Oil Seal High Pressure Oil Seal Hydraulic Pump Seal

The expert consensus emphasizes regular inspection cycles as a key strategy for maintaining the integrity of oil pump seal kits. By integrating routine checks into maintenance schedules, potential issues can be identified and addressed before they evolve into significant failures. This proactive approach is far more cost-effective and less disruptive than dealing with unexpected breakdowns. Another crucial factor is proper installation. Incorrect installation not only reduces the efficacy of the seals but can also lead to immediate failures. Therefore, ensuring installation is carried out by trained professionals, who adhere to manufacturer specifications, greatly enhances the trustworthiness and reliability of the equipment. For businesses relying heavily on engine machinery, establishing a partnership with a reputable supplier of oil pump seal kits is advisable. Suppliers who specialize in these kits possess the expertise needed to provide customized solutions tailored to specific machinery, ensuring compatibility and optimal performance. Investing in quality oil pump seal kits is not merely an expenditure; it is a strategic decision towards safeguarding the efficiency and longevity of your machinery. Doing so not only underscores expertise in understanding engine dynamics but also establishes authority and trust in professional maintenance practices. Ultimately, the oil pump seal kit, though a seemingly modest component, holds authoritative significance in the context of engine performance and reliability. By prioritizing appropriate seal kit selection, regular inspections, and professional installations, one can confidently maintain engine systems, assuring both short-term efficiency and long-term equipment health. Through informed decision-making based on proven expertise, the common pitfalls of machinery maintenance can be substantially mitigated, benefiting both operators’ peace of mind and the bottom line.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories