2 月 . 01, 2025 04:01 Back to list

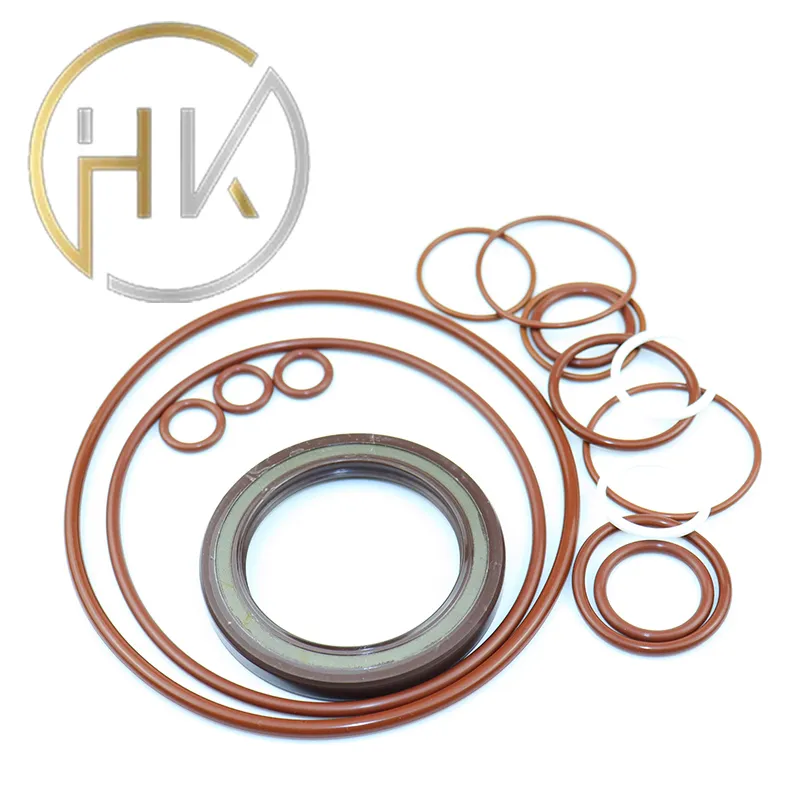

oil pump seal

Another cornerstone to effective use of an oil pump seal kit is regular inspection and maintenance. Over time, the seals may succumb to wear due to constant pressure, high temperatures, and potential exposure to harsh chemicals. A routine check not only helps preempt seal failures but is also a proactive measure to diagnose any potential cracks or abrasions that could evolve into leaks. Establishing a maintenance schedule that includes checking oil levels and inspecting seals can considerably extend the life of an oil pump system. In terms of product expertise, suppliers who provide robust after-sales service often enhance the trustworthiness and authority of their seal kits. They frequently offer technical support, installation guides, and sometimes, extended warranties, reflecting confidence in their product’s quality. From a consumer standpoint, opting for seal kits from these companies not only ensures product quality but also contributes to peace of mind regarding performance reliability. In conclusion, an oil pump seal kit, while compact in size, encompasses a realm of importance that calls for a strategic approach in both selection and application. By combining expert guidance, diligent maintenance, and a commitment to using quality, compatible products, machinery operators can ensure that the humble seal kit contributes to peak oil pump performance effectively and sustainably. Embracing this proactive mindset not only preserves the efficiency of the machinery but also serves as a testament to competence and professionalism in machinery maintenance and optimization.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories