3 月 . 04, 2025 01:01 Back to list

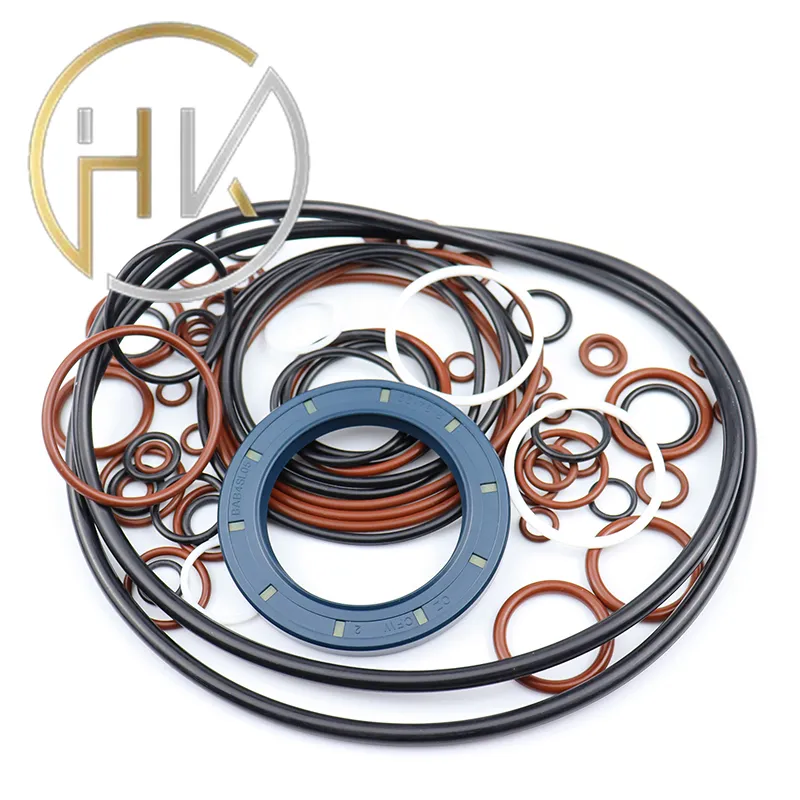

metric wiper seals

Authoritative insights from industry leaders highlight the growing trend towards customized solutions. As machinery becomes more sophisticated, the need for tailored sealing solutions becomes evident. Companies specializing in metric wiper seals offer bespoke designs that cater to unique industrial needs, thereby solidifying their position as trusted partners in machinery maintenance and innovation. Trust in these components is bolstered by their proven track record. Many companies have documented significant reductions in maintenance costs and downtime, attributing these improvements to the robust performance of metric wiper seals. Testimonials from managers and engineers alike attest to their indispensable role in preserving asset integrity and enhancing overall operational efficiency. In an era where efficiency and reliability govern industrial progress, metric wiper seals stand out as critical elements ensuring smooth and uninterrupted operations. Their design, coupled with the evolving landscape of industrial demands, highlights the importance of continuous research and development in seal technology. The commitment to innovation and quality not only propels the industry forward but also assures businesses of the dependability and efficiency required to thrive in competitive markets. In conclusion, metric wiper seals epitomize the convergence of experience, expertise, authority, and trustworthiness. As vital components in a range of industrial applications, they symbolize the seamless integration of engineering excellence and industry know-how, driving improvements in machinery reliability and performance. With ongoing advancements, the future of metric wiper seals appears promising, poised to meet and exceed the challenges of modern industry needs.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories