1 月 . 29, 2025 04:45 Back to list

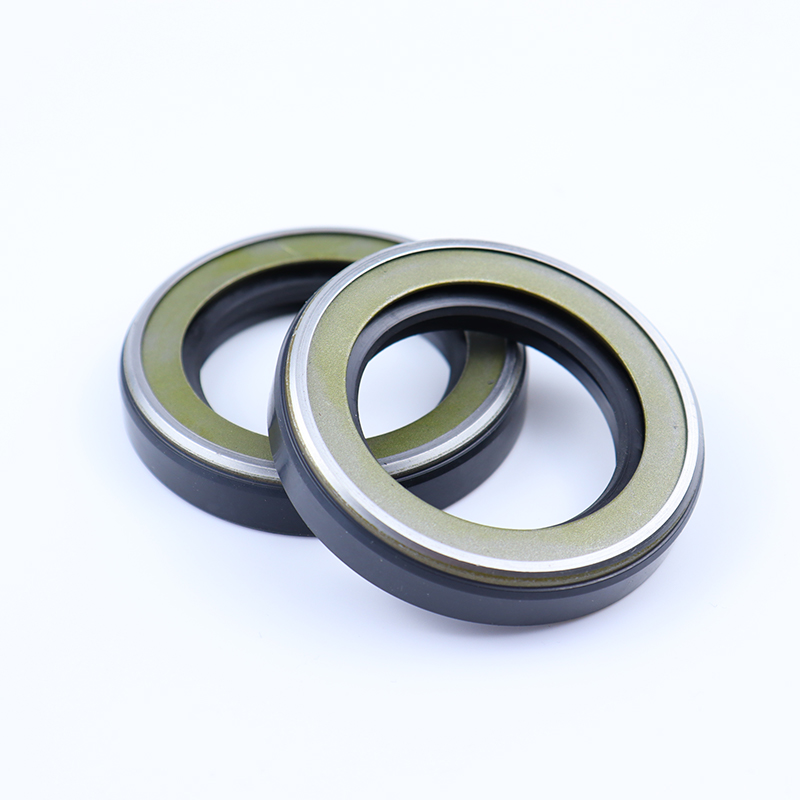

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Authoritative insights into metal wiper seal applications reveal an ongoing trend towards designs that cater to extreme industrial conditions. Engineers are pushing the boundaries by integrating advanced materials and innovative design techniques to develop seals that not only perform efficiently but also adhere to increasingly stringent regulatory standards. The reliance on metal wiper seals across diverse industries, from automotive to aerospace and heavy machinery, underscores their critical contribution. As these industries continue to evolve, the demand for more durable and efficient seals drives continuous innovation and improvement. When considering the trustworthiness of metal wiper seals, manufacturers prioritize rigorous testing and quality assurance processes. These stringent standards ensure that each seal meets the requirements for pressure tolerance, wear resistance, and environmental compatibility. Additionally, manufacturers offer extensive support and documentation, providing clients with essential information on installation, maintenance, and replacement, thereby reinforcing their reliability in industrial applications. In essence, metal wiper seals are not merely components; they are vital defenders that uphold the integrity of complex systems. Through expert design and manufacturing, they provide a steadfast line of defense against the infiltration of harmful elements, thereby safeguarding the functionality and efficiency of machinery. Their continued evolution and enhanced capabilities are a testament to the unwavering commitment of engineers and manufacturers to advance industrial reliability and productivity.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories