10 月 . 16, 2024 17:04 Back to list

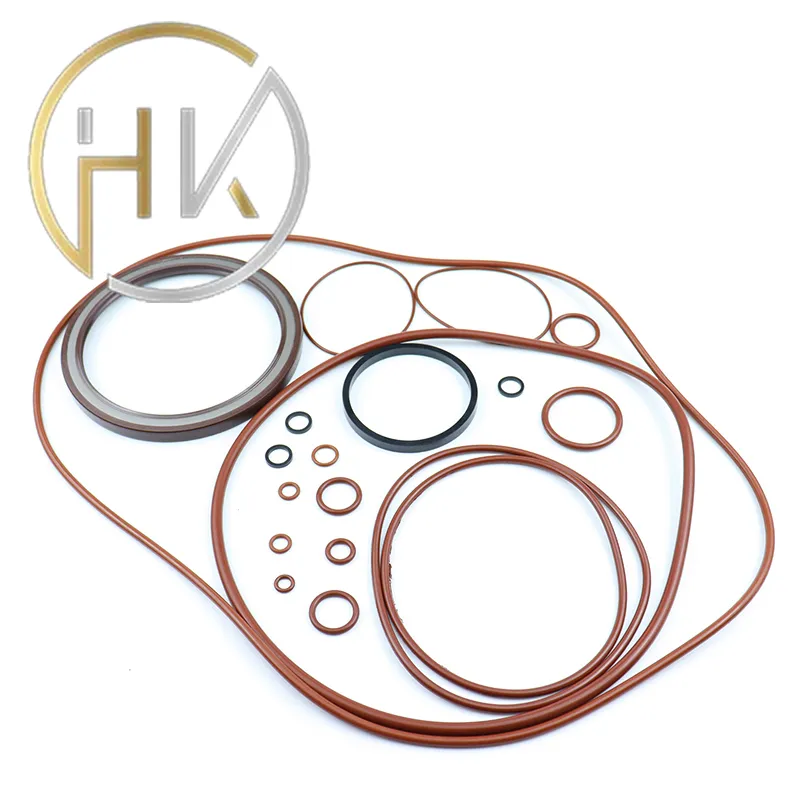

metal wiper seal

Understanding Metal Wiper Seals A Key Component in Sealing Technology

Metal wiper seals are an essential innovation in the field of sealing technology, playing a critical role in various applications across numerous industries. With the increasing demand for high-performance sealing solutions, metal wiper seals have gained prominence due to their durability, efficiency, and ability to provide a reliable barrier against contamination and fluid leakage.

What are Metal Wiper Seals?

Metal wiper seals are specialized sealing components designed to protect moving parts from debris and contamination while preventing the escape of fluids. They typically consist of a metal frame with an elastomeric sealing element that can adapt to changing conditions. The primary function of a wiper seal is to wipe away contaminants that may accumulate on the rod or shaft, thus enhancing the longevity and performance of machinery.

Why Use Metal Wiper Seals?

The advantages of metal wiper seals are numerous. First and foremost, their robust construction makes them suitable for harsh operating environments where traditional seals might fail. They are capable of withstanding extreme temperatures, pressures, and exposure to various chemicals, making them ideal for industries such as automotive, aerospace, construction, and manufacturing.

Another significant benefit is their ability to reduce wear on moving parts. By effectively keeping dirt, dust, and other contaminants out of bearing and sealing interfaces, metal wiper seals prolong the life of equipment and reduce maintenance costs. Additionally, their design allows for a low friction operation, which is crucial for systems that require precise movement and control.

Applications of Metal Wiper Seals

metal wiper seal

Metal wiper seals are versatile and can be found in a variety of applications. In the automotive industry, they are commonly used in shock absorbers and struts to ensure smooth operation by keeping contaminants at bay. In hydraulic cylinders, metal wiper seals are essential in preventing fluid leaks and protecting the internal components from wear.

Moreover, these seals play a crucial role in heavy machinery, such as excavators and loaders, where exposure to dirt and grime is prevalent. In aerospace applications, metal wiper seals are utilized in landing gear and other critical components where reliability and performance are paramount.

Challenges and Innovations

Despite their many advantages, metal wiper seals are not without challenges. As technology evolves, the demand for even higher performance and more specialized seals continues to grow. Manufacturers are responding by investing in new materials and production techniques to enhance the functionality of metal wiper seals.

Innovations such as coatings that improve wear resistance and designs that offer better adaptability to dynamic conditions are becoming increasingly common. Furthermore, advancements in materials science are enabling the development of seals that can maintain their integrity and effectiveness in extreme environments.

Conclusion

In summary, metal wiper seals are a vital component of contemporary sealing technology, offering exceptional durability and protection against contaminants in various industrial applications. As industries continue to evolve and face new challenges, the importance of effective sealing solutions like metal wiper seals will only increase. Emphasizing reliability and performance, these seals help ensure that machinery operates smoothly and efficiently, ultimately contributing to improved productivity and reduced operating costs.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories