2 月 . 16, 2025 08:47 Back to list

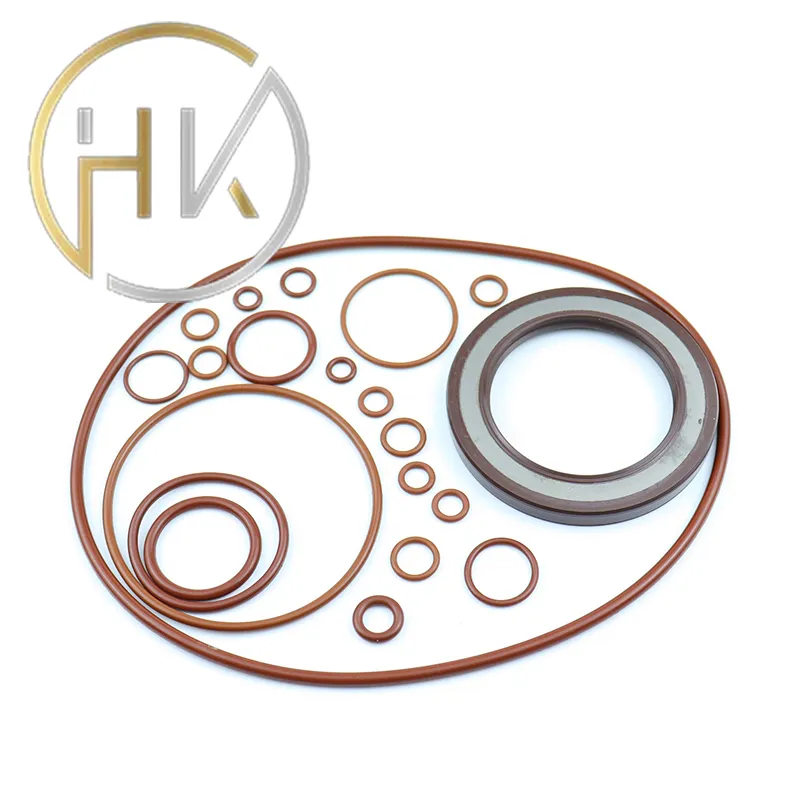

oil seals

Selecting the appropriate oil seal requires expertise and understanding of the equipment’s operating conditions. Factors such as speed, pressure, and fluid type must be considered to prevent premature seal failure. Engaging a professional for consultation can significantly enhance the decision-making process. A well-informed expert can provide insights into the latest advancements in seal technology, such as new composite materials or seal designs that offer superior performance in challenging conditions. Regular maintenance and inspection of oil seals are paramount to ensure their optimal performance. Over time, even the most durable oil seals can deteriorate due to factors such as excessive heat, vibration, or chemical attack. An effective maintenance strategy might include periodic inspections for wear or damage, as well as ensuring that seals are replaced at intervals recommended by the equipment manufacturer to avoid unexpected failures and costly repairs. Investing in high-quality industrial oil seals from reputable suppliers can amplify machinery reliability and efficiency. Quality seals come with warranties and are often subjected to rigorous quality control measures, providing assurance to businesses that their operations will not be compromised by substandard components. Partnering with trusted manufacturers who prioritize continuous innovation and support can further elevate the operational standards and integrity of industrial machinery. The role of industrial oil seals extends beyond mere mechanical function. In an era where machine downtime equates to loss of productivity and revenue, the reliability of such components is integral to maintaining competitive efficiency. They are indispensable to diverse industries, from automotive to aerospace, offering a seamless union of expertise, precision, and trustworthiness within the realm of industrial maintenance and manufacturing.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories