9 月 . 17, 2024 03:18 Back to list

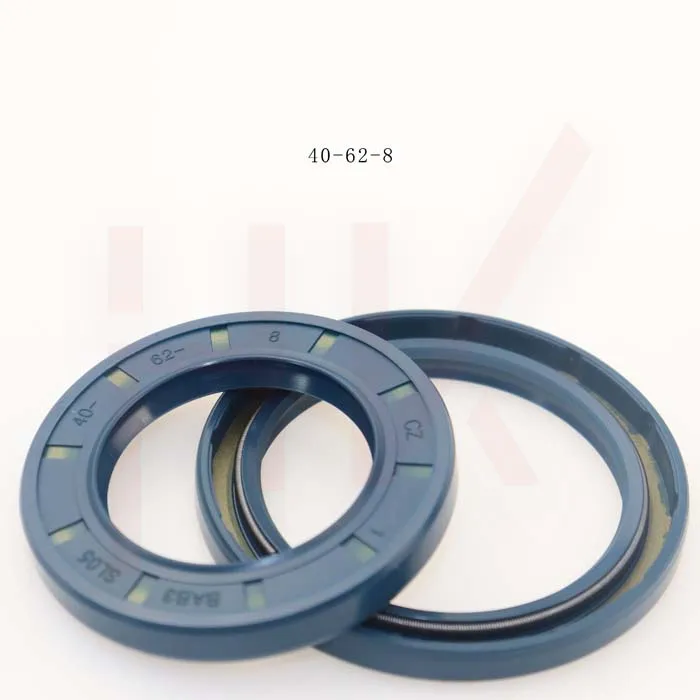

High-Quality Industrial Oil Seals - Reliable Sealing Solutions

Industrial oil seals are essential components in various machinery and equipment, playing a crucial role in maintaining the efficiency and longevity of mechanical systems. These seals are designed to prevent the leakage of fluids, particularly oil, while also keeping contaminants such as dust, dirt, and water from entering critical areas. By effectively controlling the flow of lubricants, oil seals ensure that moving parts operate smoothly and reduce wear and tear.

One of the primary functions of industrial oil seals is to safeguard bearings, gears, and other mechanical components from contamination that can lead to premature failure. For instance, in a manufacturing plant where machinery operates under high pressure and temperature conditions, oil seals play a pivotal role in preserving the integrity of lubricants. They help maintain the necessary oil film on surfaces, facilitating proper lubrication and minimizing friction.

An important aspect of oil seal design is the selection of materials. Industrial oil seals are typically made from a range of elastomers, such as nitrile rubber, fluorocarbon, or silicone, each offering unique properties suited for different applications. For example, nitrile rubber is known for its excellent resistance to petroleum-based oils and fuels, making it a popular choice for automotive and industrial applications. On the other hand, fluorocarbon seals are ideal for high-temperature environments, where resistance to extreme conditions is paramount.

industrial oil seals

The installation and maintenance of industrial oil seals are also critical. Proper alignment and seating during installation can significantly extend the operational life of the seal. Additionally, regular inspection is recommended to identify signs of wear or damage, such as cracks or deformation, which can compromise the seal's effectiveness. Timely replacement of worn seals is essential to prevent leaks and maintain optimal performance in machinery.

In conclusion, industrial oil seals are a vital component in the reliability and efficiency of mechanical systems. Their ability to prevent fluid leakage and protect against contamination makes them indispensable in various industries, including automotive, manufacturing, and aerospace. By understanding their design, material properties, and maintenance requirements, industries can enhance the performance and lifespan of their equipment, ultimately leading to improved productivity and reduced operational costs. Investing in high-quality oil seals and ensuring their proper management is a strategic move for any organization keen on optimizing their machinery's functionality.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories