11 月 . 01, 2024 17:30 Back to list

Hydraulic Seal Maintenance and Repair Techniques for Optimal Performance

Hydraulic Seal Repair A Comprehensive Guide

Hydraulic systems are crucial in various industrial applications, providing power and precision in machinery ranging from construction equipment to manufacturing processes. However, effective operation heavily relies on the integrity of hydraulic seals. Over time, seals can wear out or become damaged due to factors such as pressure fluctuations, temperature changes, and contamination, ultimately leading to leaks and system failures. Therefore, understanding the importance of hydraulic seal repair is vital for maintaining optimal performance and minimizing downtime.

Understanding Hydraulic Seals

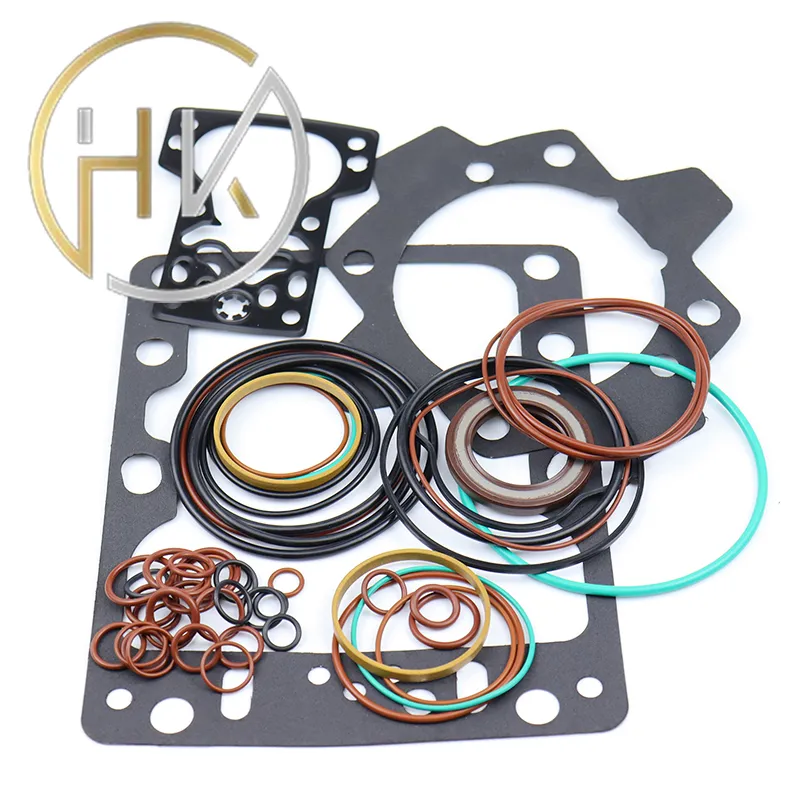

Hydraulic seals are designed to prevent the leakage of hydraulic fluid while ensuring that pressure is maintained within the system. These seals can be made from various materials, including rubber, polyurethane, and metal, each selected based on the specific requirements of the application, including temperature, pressure, and fluid compatibility. Common types of hydraulic seals include O-rings, piston seals, rod seals, and backup rings.

Signs of Seal Failure

Identifying potential seal failures early can save time and money. Some common signs of hydraulic seal failure include

1. Fluid Leaks This is the most obvious sign. If you notice hydraulic fluid pooling around machinery or equipment, it's critical to investigate the cause. 2. Increased Maintenance Requirements Frequent repairs or increased fluid replenishment can indicate that seals are failing.

3. Decreased Efficiency If machinery is underperforming or experiencing erratic movements, it may stem from seal degradation.

hydraulic seal repair

Hydraulic Seal Repair Process

Repairing hydraulic seals involves several steps to ensure a successful fix

1. Diagnosis The first step is to accurately identify the problem. This may involve inspecting the hydraulic system for leaks, damaged seals, or signs of fluid contamination.

2. Disassembly Once the problem is identified, carefully disassemble the related components to access the seals. Be sure to follow the manufacturer's guidelines to avoid further damage.

3. Inspection and Cleaning Examine the seals and surrounding components for damage. Clean any debris or contaminants that could affect the new seal installation.

4. Seal Replacement If the seals are found to be damaged, replace them with new ones of the same specifications. It's crucial to ensure that the new seals are compatible with the hydraulic fluid and operating conditions.

5. Reassembly and Testing After replacing the seals, reassemble the components, ensuring everything is correctly aligned and tightened. Conduct a thorough test to check for proper operation and eliminate any leaks.

Conclusion

Proper maintenance and timely repair of hydraulic seals are essential for the longevity and reliability of hydraulic systems. By recognizing the signs of seal failure and understanding the repair process, operators can significantly reduce downtime and avoid costly repairs. Regular inspections and preventive maintenance will not only enhance the performance of hydraulic equipment but also improve overall efficiency in industrial operations. Investing in hydraulic seal repair knowledge is, therefore, a crucial step for any business that relies on hydraulic systems.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories