3 月 . 04, 2025 11:20 Back to list

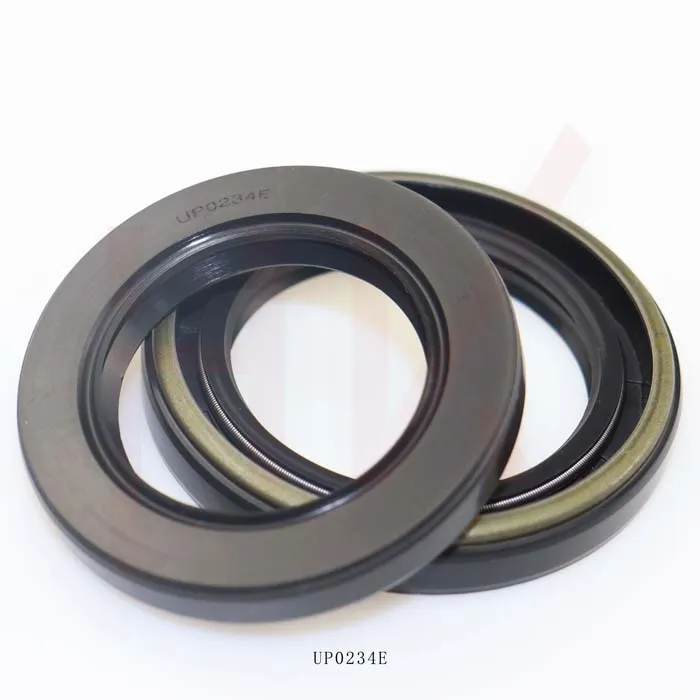

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

In industries where reliability is non-negotiable, such as aerospace or heavy machinery, the authoritativeness of hydraulic rod wiper seal suppliers is built over decades. These established brands invest heavily in research and development, ensuring their seals not only meet but exceed international standards. When sourcing seals, manufacturers' reputability should weigh just as heavily as the cost-benefit analysis. Opting for less credible sources might offer short-term savings but can lead to long-term setbacks in performance. Trustworthiness in the supply of hydraulic rod wiper seals is demonstrated through consistent quality and reliable customer support. The best suppliers offer warranties and comprehensive support, fostering trust and establishing long-term partnerships. Trust is also built by transparency in communication—clients need to understand what they are purchasing and how it will benefit their specific use cases. In conclusion, hydraulic rod wiper seals, though small, are monumental in ensuring the proper functioning of hydraulic systems. Experience has shown their necessity; expertise underscores the focus on design and material selection; authoritative suppliers enhance confidence through quality assurance, and trustworthiness is borne out in consistent, transparent, and collaborative support. For businesses looking to sustain high operational standards, committing to the right wiper seals is a decision backed not just by functionality but by enhanced product reliability and extended machinery longevity.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories