2 月 . 14, 2025 12:10 Back to list

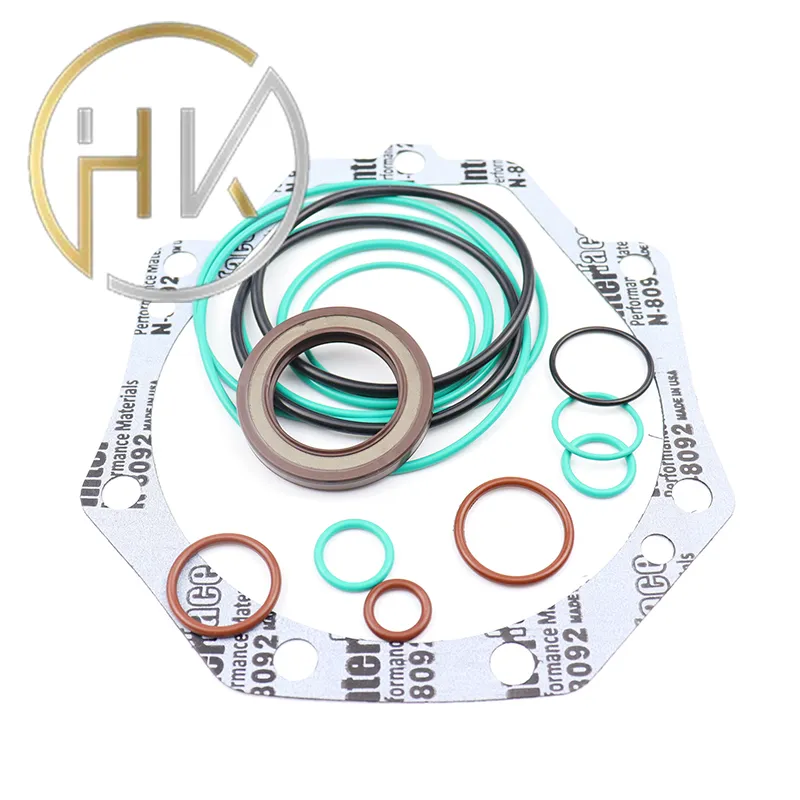

hydraulic ram seal replacement

After replacing the seal, reassemble the hydraulic ram, reconnect it to the system, and gradually repressurize to test the integrity of the installation. Monitor the system for signs of irregular operation or leaks over the subsequent operational period. Successful replacement should restore the hydraulic ram to optimal performance, resulting in efficient force transmission and reduced risk of operational downtime. Beyond the mechanics of replacement, understanding the conditions leading to seal failure enhances proactive maintenance strategies. Regularly check hydraulic fluid quality, as contaminants and incorrect fluid types can accelerate seal degradation. Implement effective filtration and fluid conditioning systems to prolong seal life and system efficiency. Long-term reliability in hydraulic systems demands not only attention to immediate faults but also an ongoing commitment to preventive maintenance. Developing a schedule for routine inspections and replacements based on operational intensity and environmental conditions ensures sustained performance and longevity of hydraulic components. Elevating your expertise in hydraulic ram seal maintenance empowers you with the capacity to mitigate the risk of unscheduled downtimes, prolong equipment life, and improve operational safety standards. By adopting a thorough, informed approach to seal replacement, you align with best practices that reflect industry leadership in equipment maintenance and reliability. Trust in the industries’ standards and your growing expertise, and leverage them to foster robust hydraulic system management. This proactive stance reflects on your reputation for quality maintenance and commitment to operational excellence, setting a benchmark in the field. In summary, taking a strategic, informed approach to hydraulic ram seal replacement not only optimizes machine performance but also reinforces an ethos of reliability and technical mastery in the domain of hydraulic machinery maintenance.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories