1 月 . 23, 2025 04:38 Back to list

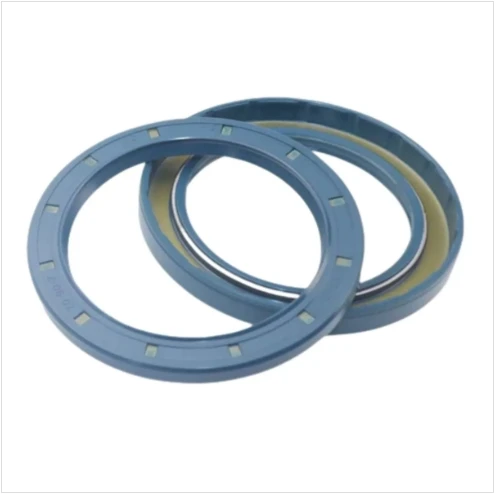

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

From a maintenance perspective, regularly inspecting and replacing hydraulic ram seal kits can prevent unexpected failures and extend the lifespan of hydraulic machinery. Technicians are recommended to follow a maintenance checklist that includes checking for physical wear, assessing the condition of hydraulic fluid, and testing the system under load conditions. Documented maintenance records and routine checks not only ensure smooth operations but also build a framework of trust during audits and inspections. The authoritativeness of hydraulic ram seal kits is also reflected in their adherence to industry standards and certifications. ISO 9001 certification, for instance, is a hallmark of quality assurance, indicating that the manufacturing processes involve stringent quality control measures. Purchasing seal kits from reputable suppliers guarantees that the products have undergone rigorous testing and meet the performance criteria set by leading industry organizations. Trustworthiness in product procurement and deployment is assured when businesses establish relationships with accredited distributors and manufacturers of hydraulic seal kits. Genuine products are more likely to provide dependable service compared to cheaper, unverified alternatives that can result in expensive repairs and potential safety hazards. In addition, customer testimonials and case studies serve as valuable resources for companies seeking to verify the performance and reliability of a hydraulic ram seal kit. Ultimately, the investment in a hydraulic ram seal kit is an investment in operational efficiency, safety, and longevity of hydraulic systems. Being informed about product specifications, application expertise, and having an emphasis on regular maintenance can lead to significant cost savings and enhanced equipment performance. With advancements in technology and manufacturing processes, hydraulic ram seal kits continue to evolve, providing superior solutions for industries reliant on hydraulic power.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories