10 月 . 16, 2024 05:10 Back to list

Hydraulic Ram Seal Kit for Efficient Performance and Enhanced Durability in Machinery

Understanding Hydraulic Ram Seal Kits Importance, Functionality, and Maintenance

Hydraulic systems play a crucial role in modern machinery and equipment, providing the power needed for heavy lifting and movements with efficiency and precision. One of the critical components in these systems is the hydraulic ram, a device that converts fluid pressure into hydraulic energy. Ensuring that the hydraulic ram operates effectively often hinges on the integrity of the seals, which leads us to the importance of hydraulic ram seal kits.

What is a Hydraulic Ram Seal Kit?

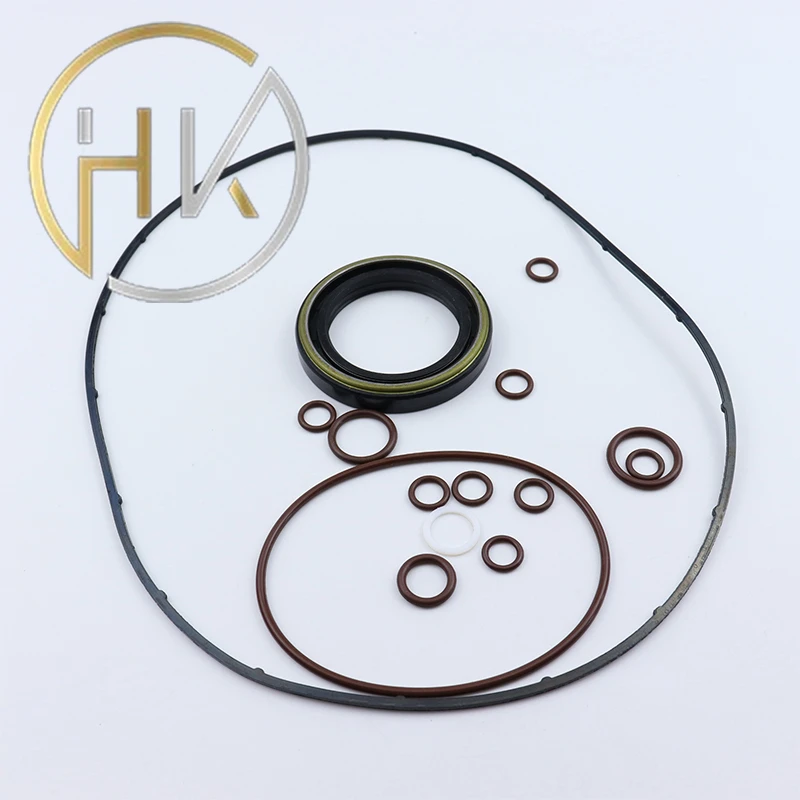

A hydraulic ram seal kit includes various seals specifically designed for hydraulic rams. These seals prevent fluid leakage, maintain pressure, and protect internal components from contaminants. Usually, these kits consist of O-rings, backup rings, lip seals, and possibly wear rings, all tailored to fit the specifications of specific hydraulic ram models.

The materials used in these seals are crucial. They must withstand high pressure and dynamic movements while also resisting degradation from hydraulic fluids, temperature fluctuations, and, sometimes, chemical exposure. Common materials include nitrile rubber (NBR), fluorocarbon (FKM), and polyurethane, each selected based on the application and conditions of the hydraulic system.

The Importance of Hydraulic Ram Seals

The significance of hydraulic ram seals cannot be overstated. Firstly, they ensure the hydraulic fluid remains contained within the system, preventing leaks that could lead to loss of pressure and inefficient operation. A small leak might seem trivial, but over time, it can lead to significant fluid loss, reduced performance, and increased operating costs.

Secondly, these seals shield the internal parts of the hydraulic ram from dirt, debris, and moisture. Contaminants can cause abrasion, leading to wear and failure of components. By maintaining a clean environment within the hydraulic ram, seals not only extend the life of the equipment but also enhance reliability and safety.

hydraulic ram seal kit

Finally, proper sealing contributes to energy efficiency. A well-sealed hydraulic ram minimizes energy waste, allowing for smoother operation and better performance. This is especially important in applications such as construction, manufacturing, and automotive industries, where operational efficiency translates to reduced costs and improved productivity.

Maintenance and Replacement

Regular maintenance of hydraulic ram seal kits is essential for optimal performance. Inspections should be conducted periodically to check for signs of wear, damage, or leakage. It is advisable to keep an eye out for changes in the operation of the hydraulic system, such as unusual noises, reduced lifting capacity, or fluid accumulation around the ram.

When it becomes necessary to replace the seals, using a seal kit specific to the hydraulic ram model is crucial. Generic or ill-fitting seals can compromise the integrity of the system, leading to failures and downtime. Follow the manufacturer's guidelines for installation, ensuring that all seals are properly seated and free from debris.

Conclusion

In conclusion, hydraulic ram seal kits play a pivotal role in the performance and longevity of hydraulic systems. By preventing leaks, protecting internal components, and promoting efficient operation, these seal kits are an essential investment for businesses reliant on hydraulic machinery. Understanding their importance and ensuring regular maintenance can lead to increased equipment lifespan, reduced operational costs, and enhanced productivity in various industrial applications.

Whether you are a business owner, a technician, or simply someone interested in hydraulic systems, familiarizing yourself with hydraulic ram seal kits is vital. By prioritizing their maintenance and replacement, you can ensure your hydraulic systems continue to operate smoothly and efficiently, meeting the demanding needs of modern industry.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories