10 月 . 05, 2024 12:51 Back to list

hydraulic ram rebuild kit

Understanding Hydraulic Ram Rebuild Kits A Comprehensive Guide

Hydraulic rams are crucial components in various industrial and agricultural applications. They facilitate powerful movements through the use of hydraulic fluid, enabling efficient lifting, pushing, or pulling of heavy loads. However, like any mechanical system, hydraulic rams are subject to wear and tear over time. This situation often leads to a decline in their performance, necessitating repairs or even a complete overhaul. This is where hydraulic ram rebuild kits come into play.

What is a Hydraulic Ram Rebuild Kit?

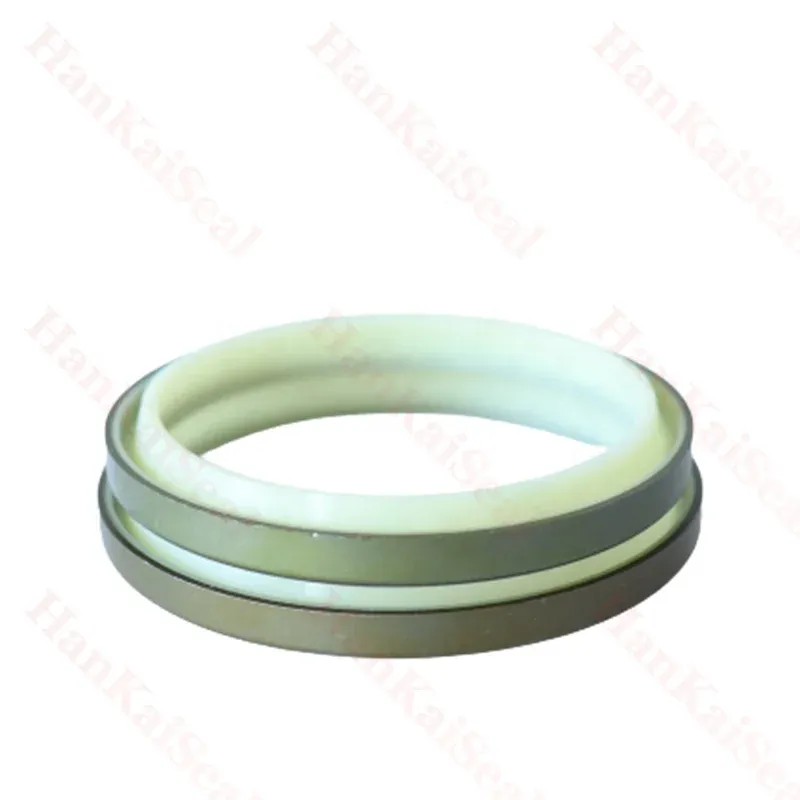

A hydraulic ram rebuild kit is a collection of components designed to restore a hydraulic ram to its original operating condition. These kits typically include a variety of parts such as seals, O-rings, gaskets, and sometimes even pistons and cylinders. The purpose of these kits is to provide all the necessary materials to fix common issues that may arise during the life of the hydraulic ram, such as leaks, loss of pressure, or decreased lifting capabilities.

Benefits of Using a Rebuild Kit

1. Cost-Effective Solution Purchasing a rebuild kit is often significantly cheaper than buying a new hydraulic ram. For businesses that rely heavily on hydraulic systems, this cost savings can be substantial.

2. Improved Performance Over time, the effectiveness of a hydraulic ram can diminish due to wear on its seals and other components. By using a rebuild kit, users can restore the system to its optimal performance level, which can enhance overall operational efficiency.

3. Ease of Maintenance Rebuild kits simplify maintenance efforts. With all necessary components included, operators can quickly address problems without the need to source individual parts, streamlining the repair process.

4. Sustainability Repairing rather than replacing hydraulic rams contributes to environmental sustainability. By extending the lifespan of existing equipment, businesses can reduce waste and conserve resources.

Common Components of a Hydraulic Ram Rebuild Kit

A typical hydraulic ram rebuild kit may include

hydraulic ram rebuild kit

- Seals and O-Rings These are vital in preventing leaks. Over time, they can wear out or become brittle, leading to hydraulic fluid loss and reduced efficiency. - Gaskets Used to seal joints and prevent fluid leaks between different components of the hydraulic ram. - Pistons and Cylinders In more comprehensive kits, you may find replacement pistons and cylinders that help restore the functionality of the ram.

- Instruction Manual This is crucial for users who may not be familiar with the rebuilding process. A detailed guide can help ensure the kit is used effectively.

How to Install a Hydraulic Ram Rebuild Kit

1. Safety First Before starting any repair, ensure all hydraulic pressure is released to prevent accidental injuries.

2. Disassembly Carefully disassemble the hydraulic ram, taking note of how components fit together. This step often requires specific tools, such as wrenches and screwdrivers.

3. Clean Components Clean all parts thoroughly to remove old seals and debris that could hinder the performance of new components.

4. Install New Parts Using the instruction manual, replace worn components with those from the rebuild kit. Pay special attention to the orientation of seals and gaskets.

5. Reassemble the Ram Once all new parts are installed, carefully reassemble the hydraulic ram, ensuring everything is tightened properly and fitted correctly.

6. Testing After reassembly, test the ram under controlled conditions to ensure it operates correctly and meets performance standards.

Conclusion

Hydraulic ram rebuild kits represent a practical, cost-effective way to maintain and enhance the performance of hydraulic systems. With the proper installation, these kits can significantly extend the life of hydraulic rams, contributing to more sustainable business practices while improving operational efficiency. Whether in agricultural settings or industrial applications, investing in a rebuild kit can yield considerable long-term benefits.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories