10 月 . 30, 2024 11:01 Back to list

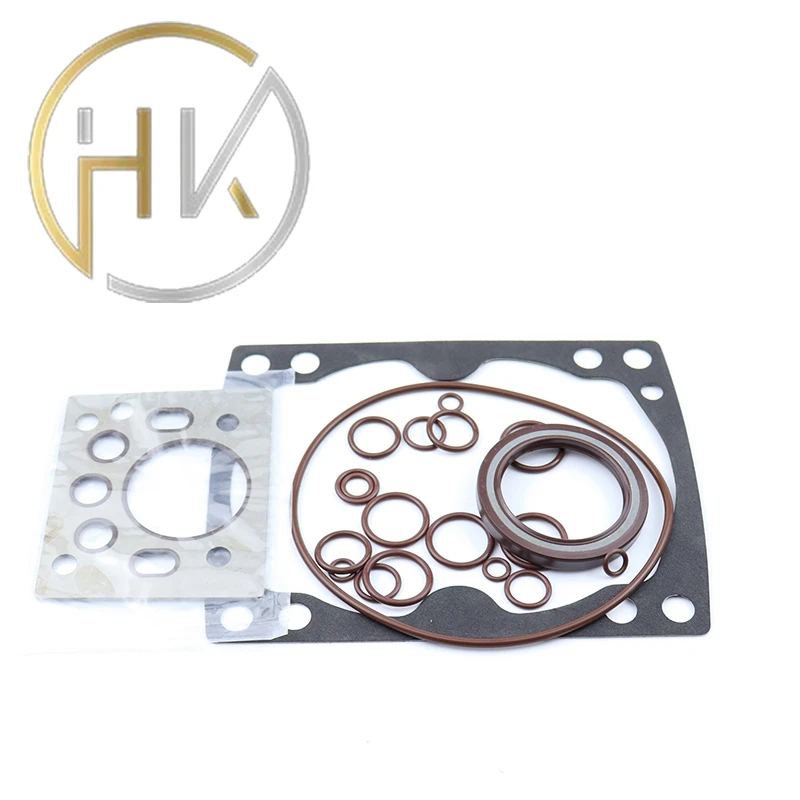

hydraulic pump seals

Understanding Hydraulic Pump Seals Essential Components for Efficiency and Longevity

Understanding Hydraulic Pump Seals Essential Components for Efficiency and Longevity

Hydraulic pumps operate by converting mechanical energy into hydraulic energy, allowing them to transmit power efficiently. To achieve optimal performance, it is vital that these pumps remain sealed and free from leaks. Hydraulic pump seals are specifically designed to maintain a barrier between the hydraulic fluid and the external environment, thus preventing any unwanted fluid escape and contamination. This is particularly important because even a small leak can lead to significant losses in fluid pressure and system efficiency.

hydraulic pump seals

There are several types of seals utilized in hydraulic pumps, each designed for specific applications and pressure conditions. One of the most common types is the O-ring seal, which offers excellent resistance to fluid pressure and is simple to install. Another type is the lip seal, which is designed to accommodate the axial movement of rotating shafts, making it ideal for dynamic applications. Additionally, composite seals, which combine various materials, can offer enhanced durability and versatility, making them suitable for harsh working conditions.

Selecting the right hydraulic pump seal is critical for ensuring the longevity and efficiency of the hydraulic system. Factors such as fluid compatibility, temperature range, and pressure conditions must be considered. Using seals that are not suitable for the specific hydraulic fluid can result in degradation and failure, leading to costly repairs and downtime. Regular maintenance and inspection of seals are also vital. Over time, seals can wear out due to friction, temperature fluctuations, or exposure to harsh chemicals. Therefore, periodic checks can help identify potential issues before they escalate.

In conclusion, hydraulic pump seals are integral to the efficient operation of hydraulic systems. They protect against fluid leaks, maintain system pressure, and enhance performance. By selecting the appropriate seals and implementing regular maintenance, industries can ensure the longevity and reliability of their hydraulic pumps, ultimately leading to improved productivity and reduced operational costs. Investing in high-quality seals and adhering to maintenance schedules will yield significant returns in the form of enhanced system efficiency and minimized downtime.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories